Material Supply

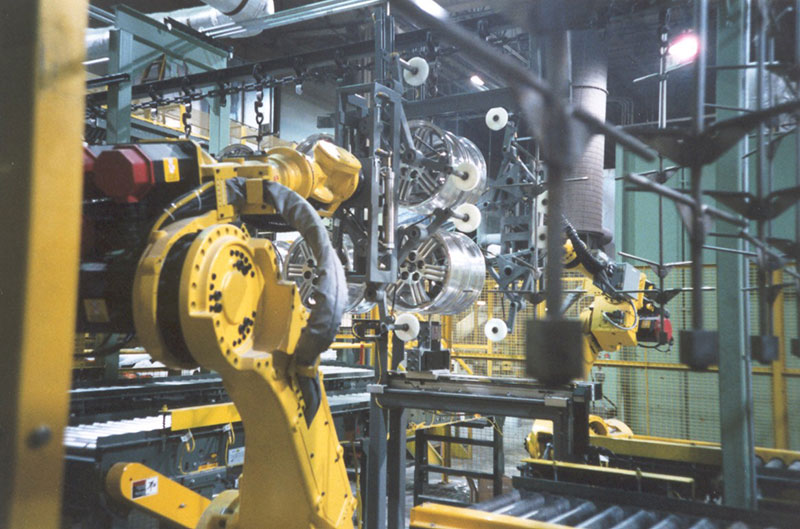

Automated material supply systems provide materials and goods for a wide range of processes. Partially manufactured parts, finished goods, components, and sub-assemblies can be supplied to other manufacturing operations with speed and efficiency.

Supporting casting, machining lines, finishing cells, and assembly lines, these material supply applications often involve robotics in systems for:

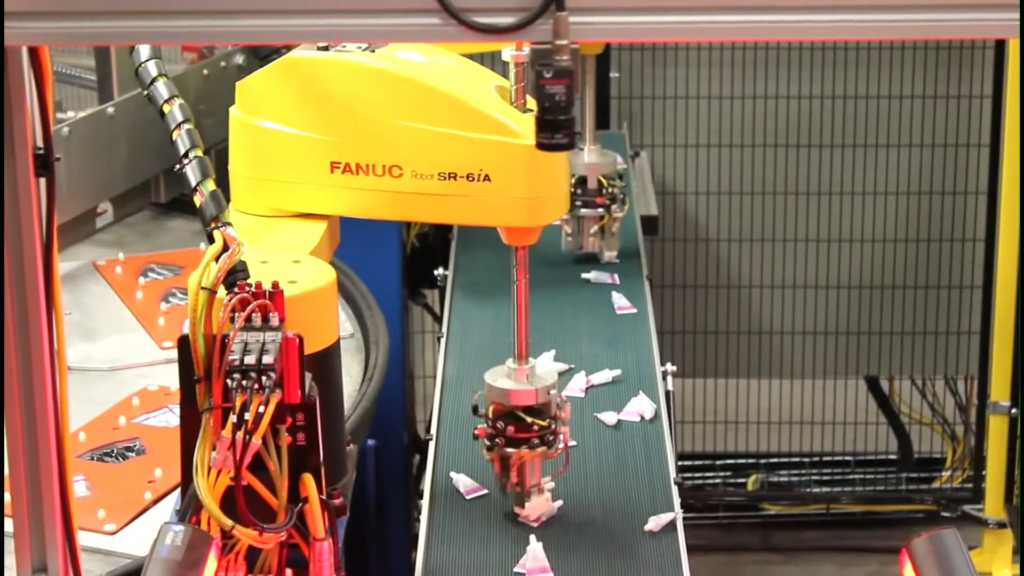

- Line Loading – depalletizing, tray unloading, and bin picking

- Line Unloading – palletizing and tray loading, tray handling, dunnage handling, pallet handling, part feeding

- Product/Part Buffering – work in process (WIP) systems

Benefits of Material Supply System Automation

In manual material supply situations, there are limitations that lead to processes falling behind.

Line load and unload systems (palletizing and palletizing) allow operators to queue up adequate numbers of parts to maintain continuity in the manufacturing line process.

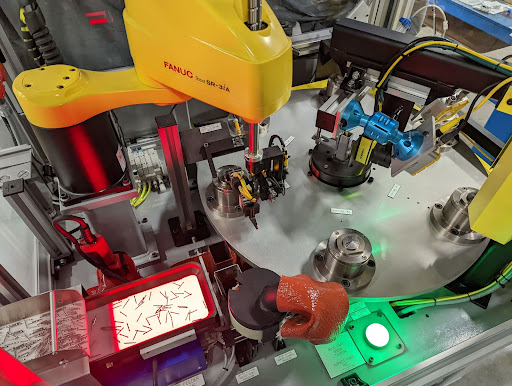

Robotic and vision based solutions provide:

- Flexibility in multi-model production

- Quick change over

- Reduced fixturing costs

- Real time model confirmation

- Adaptability for future production requirements and product changes

Code reading and traceability provide real time checks on process controls more effectively than scheduled production checks. WIP cells allow scaled buffering (similar to mini ASRS) systems that can be used for flexible manufacturing. They also allow surrounding processes to continue production, increasing uptime, even when an adjacent machine needs short term maintenance or operator intervention.

Industries that Use Material Supply Robots

- Automotive

- Transportation

- Aerospace

- Injection Molding

- Durable Goods Manufacturing

- Building Materials Production

- Consumer Goods

Why Choose Remtec?

Through our extensive experience in robotic integration, Remtec has enhanced the efficiency and productivity of many manufacturing operations with material supply robotics. We design systems with:

- Vision and mechanical based part location

- Vision inspection and model confirmation

- Customized tooling that can handle parts, trays, dunnage, and pallets without tool changing

- Automatic tool changing when needed

- Handling from bins, racks, and totes

Remtec advantages include:

- Simplified operator HMI interfaces

- Quick change over – from HMI with no manual intervention or change parts

- Customizable production tracking and traceability

- Interface to plant SCADA and data tracking systems

- Secondary process in the same robotic cell

Remtec also offers you the advantage of extensive experience in identifying the most efficient and cost-effective equipment to achieve your process goals while staying within the scope of your budget. We develop a thorough cost/benefit analysis for your team to see the justification for your robotic automation investment.

If you are new to robotics, we will work with your company to make the integration process easy and accessible.