Machine Vision

Problems with process inefficiencies, product quality, and uncaught errors cost businesses greatly in terms of lost productivity, missed delivery deadlines, and incorrect orders.

These losses result in lower profits and even damage to the reputation of a business. Thorough quality control procedures can only go so far, and staffing qualified personnel to inspect products and processes can be costly.

Robotic vision inspection technology offers businesses of all sizes a dependable solution for quality control issues.

Explore Our Integrated Systems

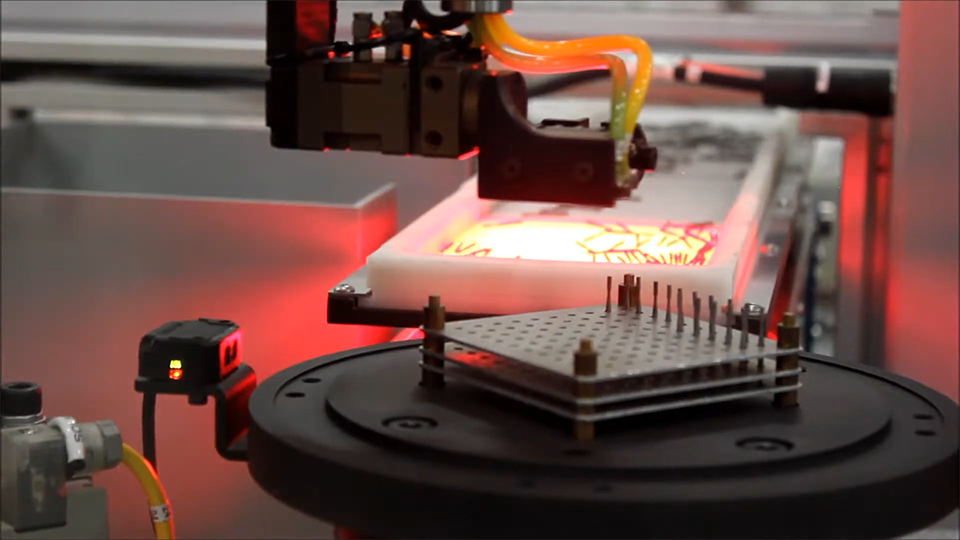

Robotic vision inspection systems have become increasingly powerful and flexible, allowing inspection tasks to be integrated into robotic work cells. Robotic inspection systems offer substantial cost savings over traditional labor intensive inspection solutions.

Quality in manufacturing improves with robotic vision inspection because robots can inspect every part produced. Conventional, off-line quality inspection involves checking only a small percentage of parts.

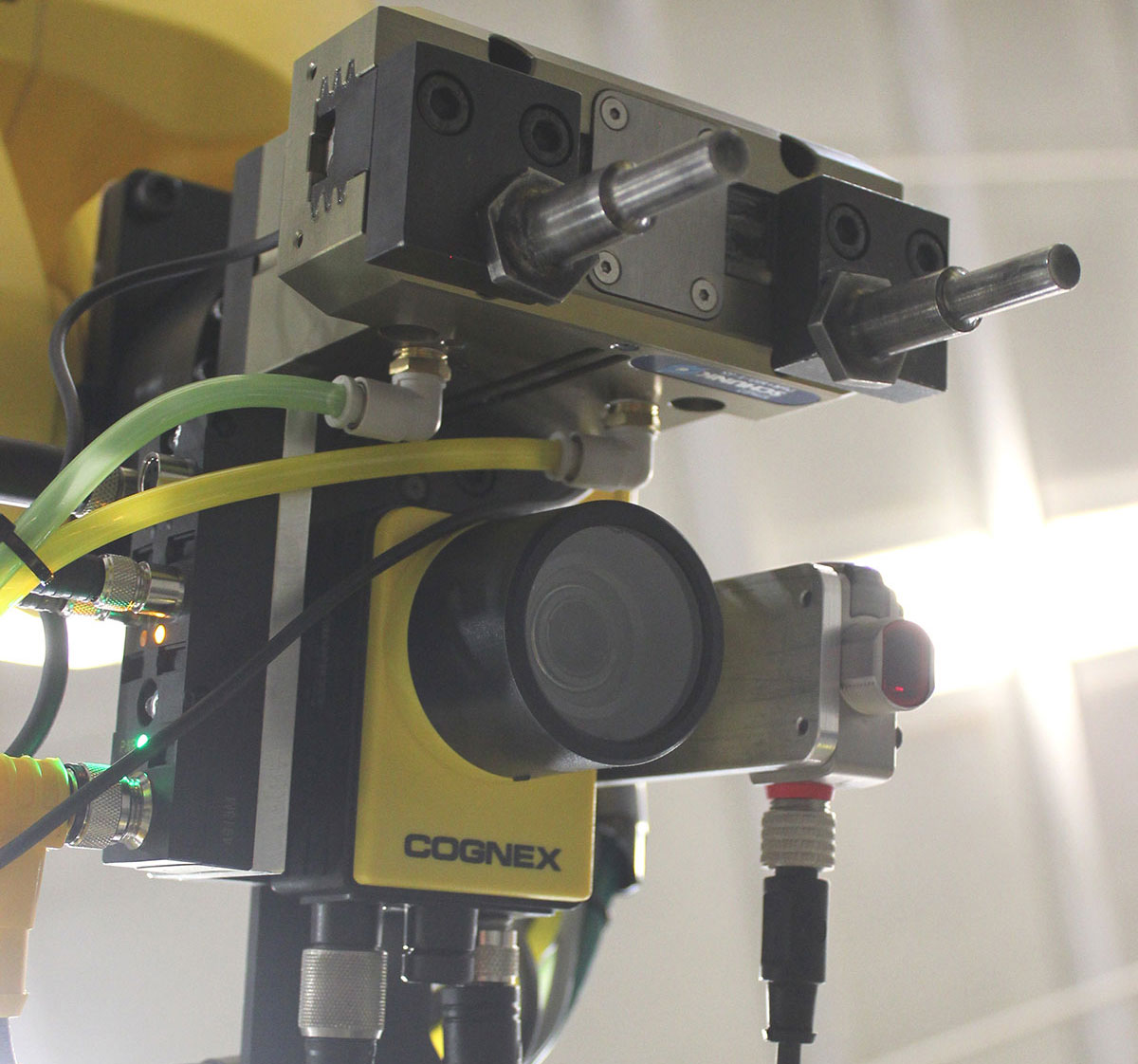

Remtec is your qualified source for robotic vision inspection system integration. Our extensive experience includes expertise in the area of 3D Line Scanning. We are a Certified Vision Specialist for FANUC, a Cognex Certified System Integrator, and an industry leader in robotic vision and inspection technology across other platforms.

Robotic vision inspection systems include different options to meet varying needs:

- 1D Robotic Vision Inspection Systems – analyze a digital signal one line at a time instead of looking at an entire picture at once. Typically detects and classifies defects on materials manufactured in a continuous process, such as paper, metals, plastics, and other non-woven sheet or roll goods.

- 2D Robotic Vision Inspection Systems – most commonly include inspection cameras that capture 2D snapshots in varying resolutions. Another type of 2D machine vision–line scan–builds a 2D image line by line. Applications include measurement, presence/absence, defect inspection, product identification, and robot guidance.

- 3D Robotic Vision Inspection Systems – usually involve multiple cameras or one or more laser displacement sensors. Multi-camera 3D vision in robotic guidance systems supplies the robot with part orientation information. 3D laser-displacement applications can use a single sensor to produce 3D results for height mapping, volume measurement, and surface inspection.

- Artificial Intelligence and Deep Learning Systems – go beyond traditional rules-based vision processes by training neural networks to feed algorithms that self-train and analyze processes based on variation from standardized “good” images. Applications include complex hard-to-solve inspections, defect inspections, poorly marked code/OCR reading, confusing background, and/or part variation.

Remtec assists both new and experienced robot users with stand-alone or integrated robotic vision inspection systems. We have worked on a wide range of industrial robotic vision inspection projects in industries such as automotive manufacturing, consumer product manufacturing, aerospace manufacturing, and general industry.

Our comprehensive services meet all project needs, from system design and development to installation and training. Contact us to discuss your project!

Machine Vision FAQs

Machine vision uses a camera to create an image, then computer vision algorithms and tools process and interpret the image. It will then instruct other components in the system to act upon this data.

1D robotic vision inspection systems analyze a digital signal one line at a time instead of looking at an entire picture at once. 2D vision inspection systems most commonly include inspection cameras that either capture 2D snapshots or builds a 2D image line by line.

Robotic vision inspection offers businesses a flexible and dependable solution for quality control issues by increasing productivity, eliminating quality slips and reducing rework. Robots can quickly and efficiently inspect every part produced, eliminating uncaught errors and incorrect orders.

Automotive manufacturing, consumer product manufacturing, aerospace manufacturing and general industry have all benefited from industrial robotic vision inspection projects.

3D robotic vision inspection systems involve multiple cameras or one or more laser displacement sensors. Multi-camera 3D vision in robotic guidance systems provides the robot with part orientation data. 3D laser-displacement applications can use just one sensor to provide 3D information for height mapping, volume measurement, and surface inspection.

As a machine vision integrator, a Certified Vision Specialist has an expert level of experience and an in-depth technical understanding of machine vision applications, including the best components and technologies for your specific project needs.