Examples of Machine Vision Use in Manufacturing

What is Machine Vision?

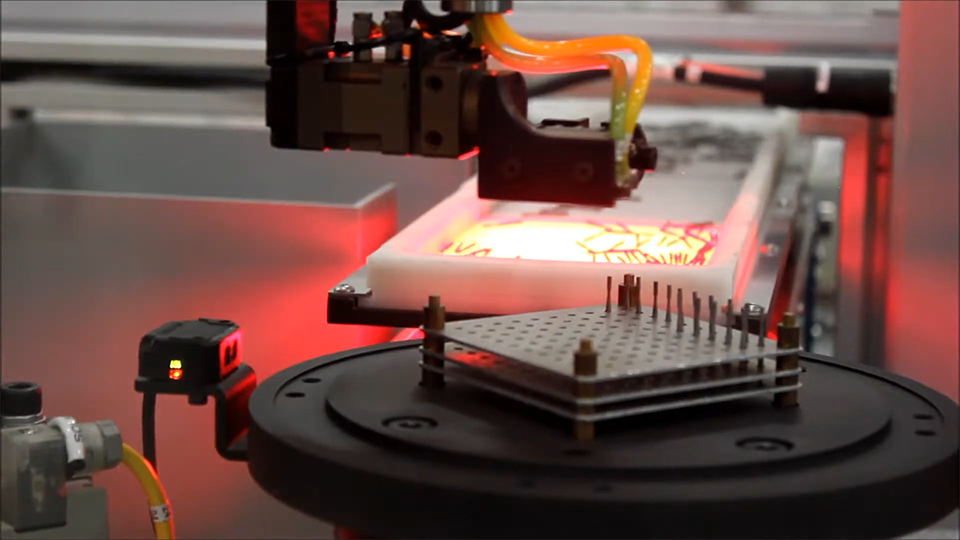

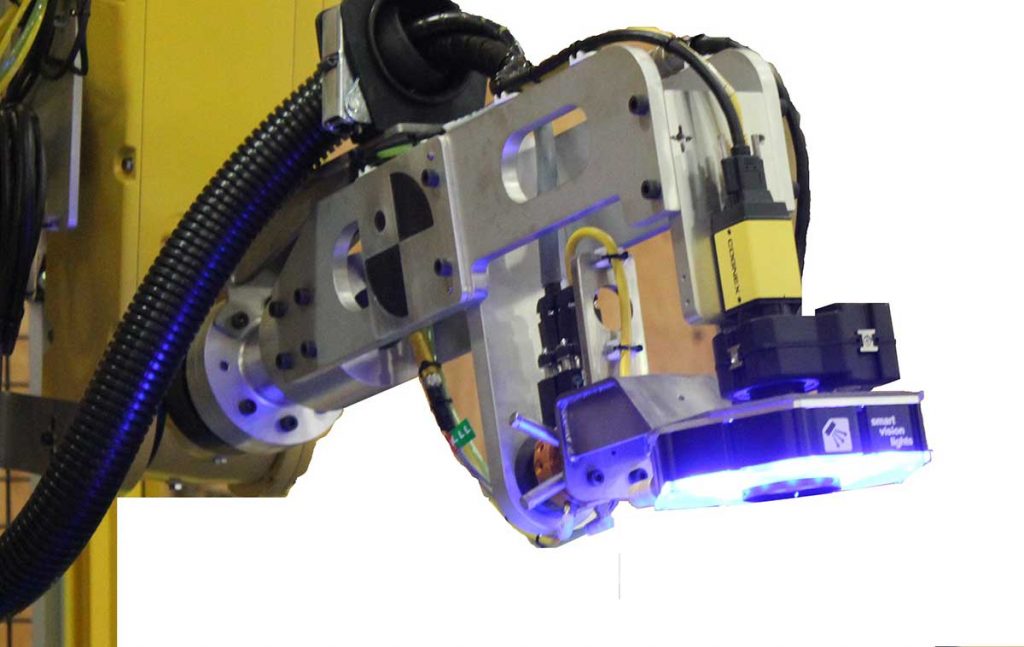

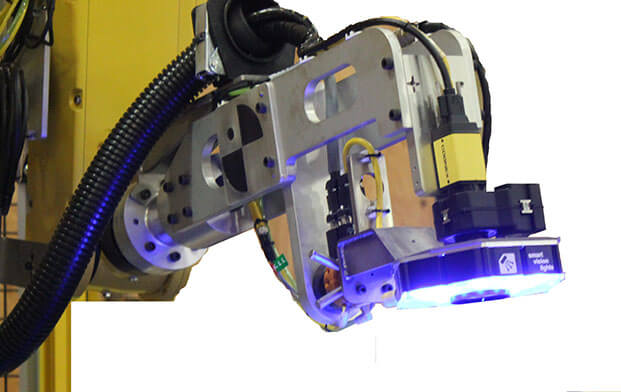

Machine vision technology uses digital sensors integrated into industrial cameras equipped with specially designed optics for capturing images. These images enable computer technology to measure, process, and analyze specific characteristics.

Machine Vision Advantages

Machine vision technology offers an unprecedented level of quality control for a growing number of industrial processes. Machine vision provides a reliable solution for increasing accuracy, consistency, and productivity.

Machine vision inspection allows supervisors to identify process inefficiencies that may otherwise go unnoticed in systems that rely solely on human detection. The advantages of machine vision technology include optimized process uptime, reduced rework, and absolute quality assurance. Unlike off-line quality inspections, which are time consuming and only inspect a small percentage of parts, machine vision inspection assures every part produced is inspected.

Another benefit of machine vision technology is the fact that these systems are highly adaptable as product designs change and evolve. Machine vision systems allow inspection tasks to be integrated into robotic work cells. Vision inspection systems actually provide significant cost savings when compared to conventional labor intensive inspection solutions.

Industries that Benefit from Machine Vision

Since these systems are flexible and highly adaptive, the benefits of machine vision technology can be applied to virtually any business. Machine vision provides a reliable solution for quality control issues for processes in a variety of industries.

Remtec has served a wide variety of markets with machine vision technology integration. Examples include:

Automotive Manufacturing

- Porosity checks

- Assembly verification

- Manufacturing process quality confirmation

- Cable routing

- Dimensional checks

Consumer Product Manufacturing

- Cap and seal verification

- Label verification and traceability

- Chip check and package quality inspection

- Fill level verification

Aerospace Manufacturing

- Process completion, code confirmation, and traceability

- Feature verification

- Component installation verification

- Safety lock wire twist count

General Industry

- OCR

- Part present

- Lot code tracking

- Surface defect examination

As an Authorized Systems Integrator for FANUC and a Certified Systems Integrator for Cognex, Remtec is available to assist both new and experienced robot users with stand-alone or integrated machine vision inspection systems. We also have accreditation as a FANUC Certified Vision Specialist.

Our team will meet all project needs, from system design and development to installation and training. Contact us to discuss your process.