Currently browsing Robotic Packing

Increase Efficiency with Remtec High Speed Packing Systems

Flexible robotic automation with Remtec high speed packaging systems provides a wide range of manufacturers with significant increases in efficiency and productivity. Our case packing systems and packing robots offer a high-speed solution for placing products in trays or loading cartons, bottles, and pouches into cases. Read on to learn how you can increase efficiency with Remtec high speed packing systems.

Robotic Case Packing Translates to Competitive Advantage

The speed and efficiency of packing processes can be improved tremendously with the implementation of robotic case packaging. Remtec and robotic case packing systems are ideal for tasks such as loading cartons, bottles, and pouches into cases, or placing products in trays. Read on to learn how robotic case packing can translate to your competitive advantage.

Remtec Sets the Table for Efficiency in Paper Dinnerware Packing Application

Remtec Meets Challenges in Candy Pouch Picking Application

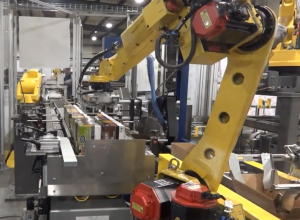

Remtec has developed applications that improve productivity and accuracy for many types of operations using advanced picking robot systems from FANUC. A great example is the M-3iA 4-axis Robot, which is being used in this application for the picking of randomized pouches of candy and placing them into buckets on a continuous infeed conveyor. This … Continued

Remtec’s Integrated Case Packing and Palletizing System

Remtec’s Robotic Case Packaging and Palletizing System is a complete End-of-Line Solution, capable of packing individual items or entire product layers at rates up to 25 cases per minute. This fully automated packaging system includes the case erector, conveyors, robotic case loader, case sealer, and case palletizer. The system can be designed to handle products … Continued