Automated Material Handling

Some operations require automation solutions for specialized processes that do not fit the traditional labels such as machine tending, palletizing, or load/unload operations. Robotically automated material handling systems fulfill a wide variety of these specialized and niche applications.

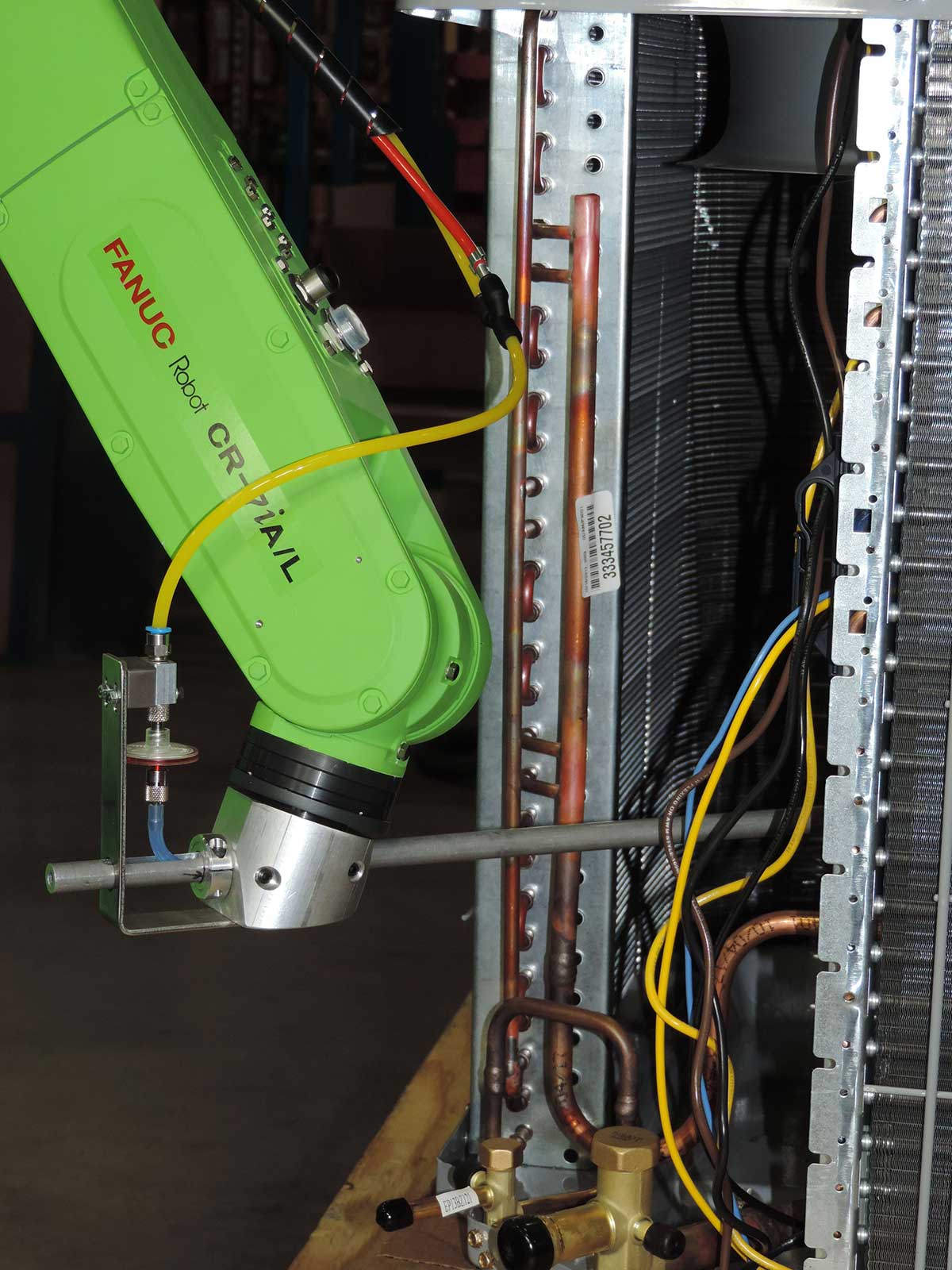

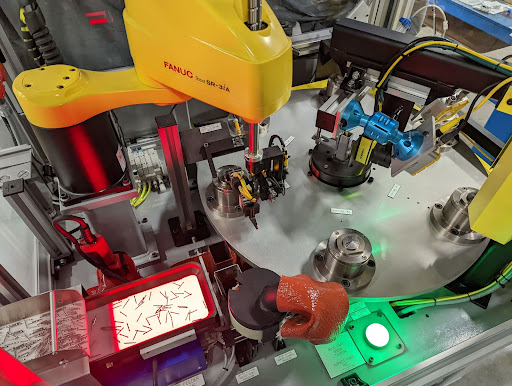

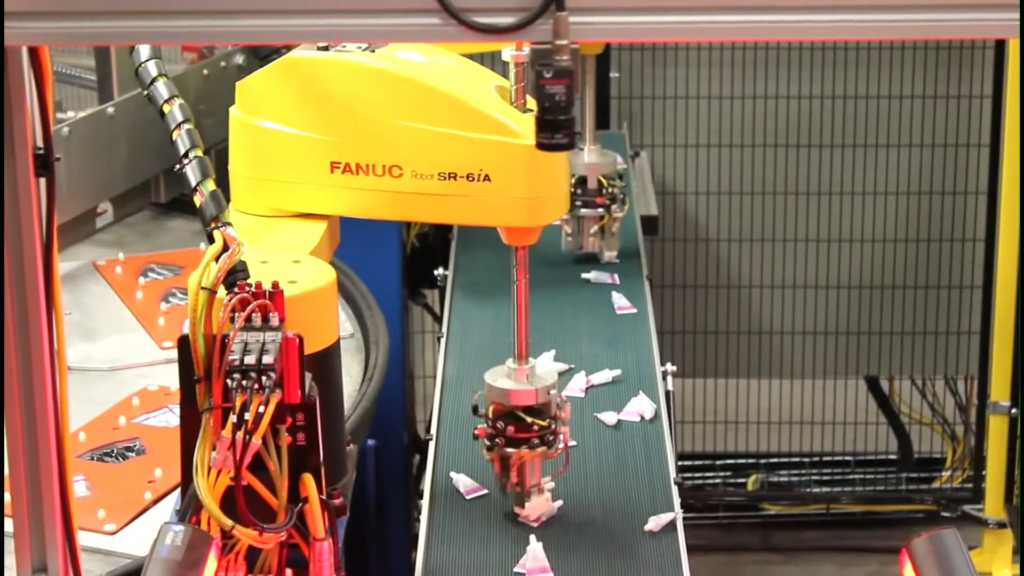

The flexibility offered by robots and collaborative robots (cobots) is ideal for unique automated material handling operations. Robots can be used alone or cobots can be used side-by-side with workers. High speed picking work cells can be used to find, pick, and order randomly oriented parts into more usable and automatable configurations.

Material handling robots can feed production lines by organizing materials and products without the aid of fixtures, pallets, totes, trays, racks, bins, or dunnage.

Explore Our Integrated Systems

How Automated Material Handling Improves Processes

Conventional hard automation is not conducive to many material handling processes due to application factors such as awkwardly shaped products. Changing production speed requirements are also challenging for off-the-shelf systems. Also, many of these unique material handling processes require built in work in progress (WIP) accommodations, which are difficult to achieve with conventional hard automation.

Robotic automated material handling systems address these challenges. Additionally, equipment costs can be matched to rate and production expectations. Since robots handle products with more precision, damage or product marking caused by other forms of hard automation are eliminated.

Industries that Benefit from Automated Material Handling

- Automotive

- Transportation

- Building Products

- Food and Beverage

- Life Sciences

Why Choose Remtec?

As one of the leading North American robotic integrators, Remtec has developed a diverse range of robotic automated material handling systems. As your robotic automation partner, Remtec offers you the benefits of:

- Truly flexible engineered automation solutions

- Cost reduction in part feeding costs

- Matched solutions (no forcing a square peg into a round hole)

- Quality and efficiency improvements

- Willingness to solve the difficult problems

- Cross application of engineering knowledge and solutions from one industry to another

- Ability to deliver reliable systems using the latest technologies

- Proof of concept testing

For customers who are new to robotics, we work with you to make the integration process easy and accessible. From employee robot training to user-friendly traditional HMI based controls, we make transitioning to robotic automation as smooth and simple as possible.