Case Palletizing

Remtec offers a range of robotic case palletizers from low-cost single SKU systems to multi-lane systems that palletize dozens of case SKUs.

Remtec’s robotic case palletizing systems offer maximum flexibility, with the ability to change SKUs automatically on demand.

The creation of new load patterns is a breeze using a PC-based graphical interface, which allows unit load patterns to be created remotely and uploaded to the system.

All of Remtec’s case palletizing systems are equipped with standard Allen-Bradley controllers, which eliminate the need for robot programming expertise on the packaging floor. A simple touch screen operator interface is provided so that the system can be operated without specialized training.

- Automatic pallet feed

- Slip sheet and/or tier sheet feeding and placement

- Dunnage destacking and placement

- Case inspection

- Case labeling

- Barcode reading, label verification, and product tracking

- Corner-posting

- Automatic load wrapping

- Automatic Guided Vehicle (AGV) interfacing

- Ethernet integration with plant and DC enterprise systems

Learn more about our robotic case palletizing solutions:

Low Cost Case Palletizer – Remtec’s Compact Robotic Palletizer is engineered to provide an economical and versatile system for case palletizing.

Multiple Infeed / Outfeed Case Palletizing System With Pallet Feeder and Stretch Wrapper – Remtec’s flexible case palletizing system is suited for a wide range of case palletizing applications.

Our robotic case palletizing experience translates to your competitive advantage. Contact us to discuss how Remtec can help you advance your business through robotic automation.

Case Palletizing FAQs

There are many situations when robotic palletizing is a great cost saving choice. Often times it is ideal when flexibility and quick changeover are desired. Other situations include when you have multiple case sizes & pallet configurations to palletize, when you need to palletize multiple products at the same time, and when you are palletizing multiple shifts per day. To find out if robotic palletizing is the most cost effective choice for your situation please contact us today.

There are a number of products that can be palletized with robotics and are essentially anything that can be stacked stably. Some example include:

- Closed top RSC cases(taped or glued)

- Trays or open top cases

- Bags

- Pails

- Manufactured parts in dunnage

Generally a single articulated arm robot palletizer can handle from 1-4 products at the same time, though gantry style robots or articulated robots on a rail can enable the palletizing system to handle 5-20+ products, as long as the total case per minute rate is within the capability of the robot being utilized.

Robotic palletizers cover a wide cost range depending on the application (product palletized, number of SKUs per system, rates, etc.) Remtec applications and sales specialists can assist you achieving your ROI goals.

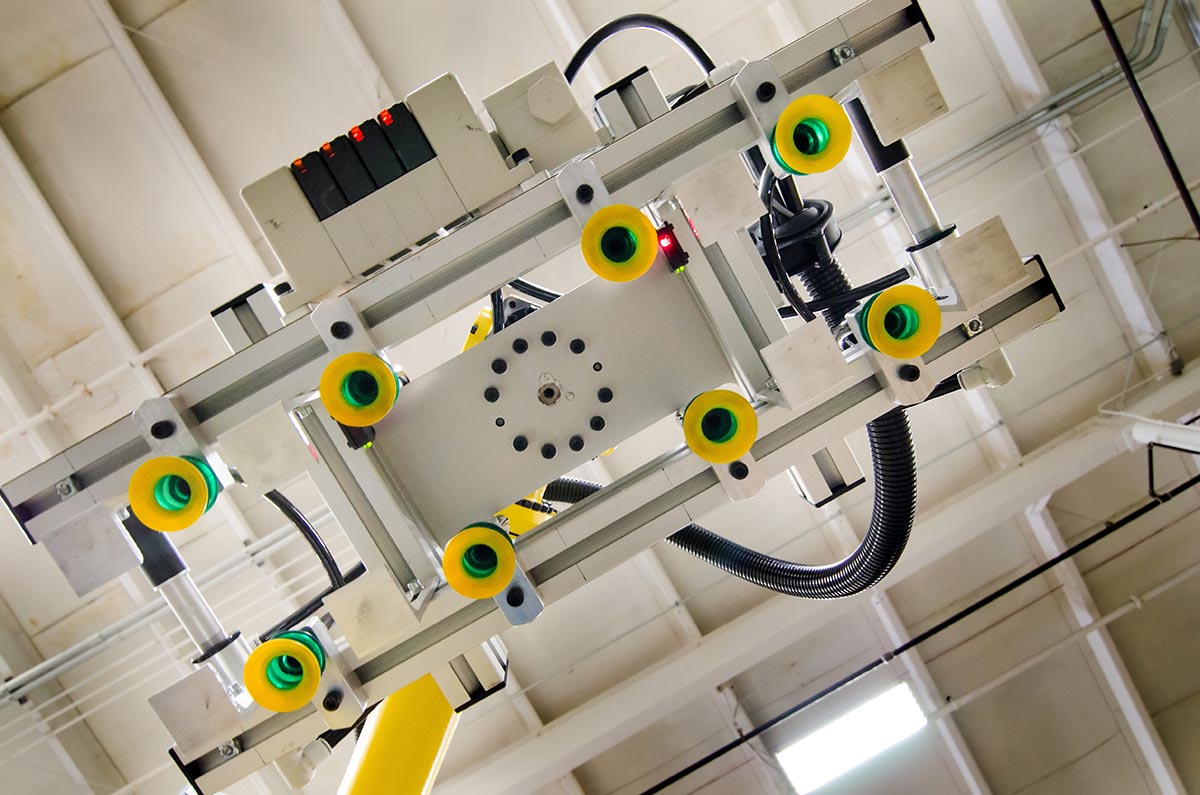

There are a number of EOAT options available each with their own specific uses. Vacuum cups or pads are generally used for closed top cases and pails. A scoop tool or a combo scoop & clamp tool is generally used for open top cases or trays. A bag tool with lifting fingers & a tamp is generally used for large bags in the 20-100 # range. Odd shaped parts are generally picked up with a custom designed clamp tool.

Many industries have enhanced productivity and efficiency with robotic palletizing, including consumer goods manufacturing, durable goods manufacturing, and food processing.