Collaborative Robotics

When considering the implementation of industrial manufacturing automation, benefits such as increased safety, enhanced production, and less rework are attractive incentives.

Some of the perceived disadvantages associated with automation, however, include cost, implementation time, and disruption to the business.

Collaborative robots offer a growing alternative to traditional work cell automation, providing robotic advantages along with an extremely high degree of flexibility in implementation.

All robotic applications (and especially collaborative applications) should include a complete system ANSI/RIA risk study by the integrator and review by the facility safety officer.

Collaborative robots work directly with people, becoming an essential part of your team. Providing integrated support to your human workforce, collaborative robots promote worker health and safety by taking over tedious, repetitive tasks, and some degree of lifting.

Collaborative robot applications include four basic operational methods:

| TYPE OF COLLABORATIVE ROBOT OPERATION | EXAMPLE |

| 1. Safety-Rated Monitored Stop | Manual Loading Station |

| 2. Hand Guiding | Operation as Assist Device |

| 3. Speed and Separation Monitoring | Replenishing Parts Containers |

| 4. Power and Force Limiting by Inherent Design or Control | Small and low force applications |

Collaborative robots are not always fenceless, but in many cases, they can be fenceless. The goal of some applications is to allow the operator to freely work with the robot, in which case collaborative robots are well suited for the task. In the case of force-limited collaborative robots, integrated technologies and design ensure the human process participant is protected.

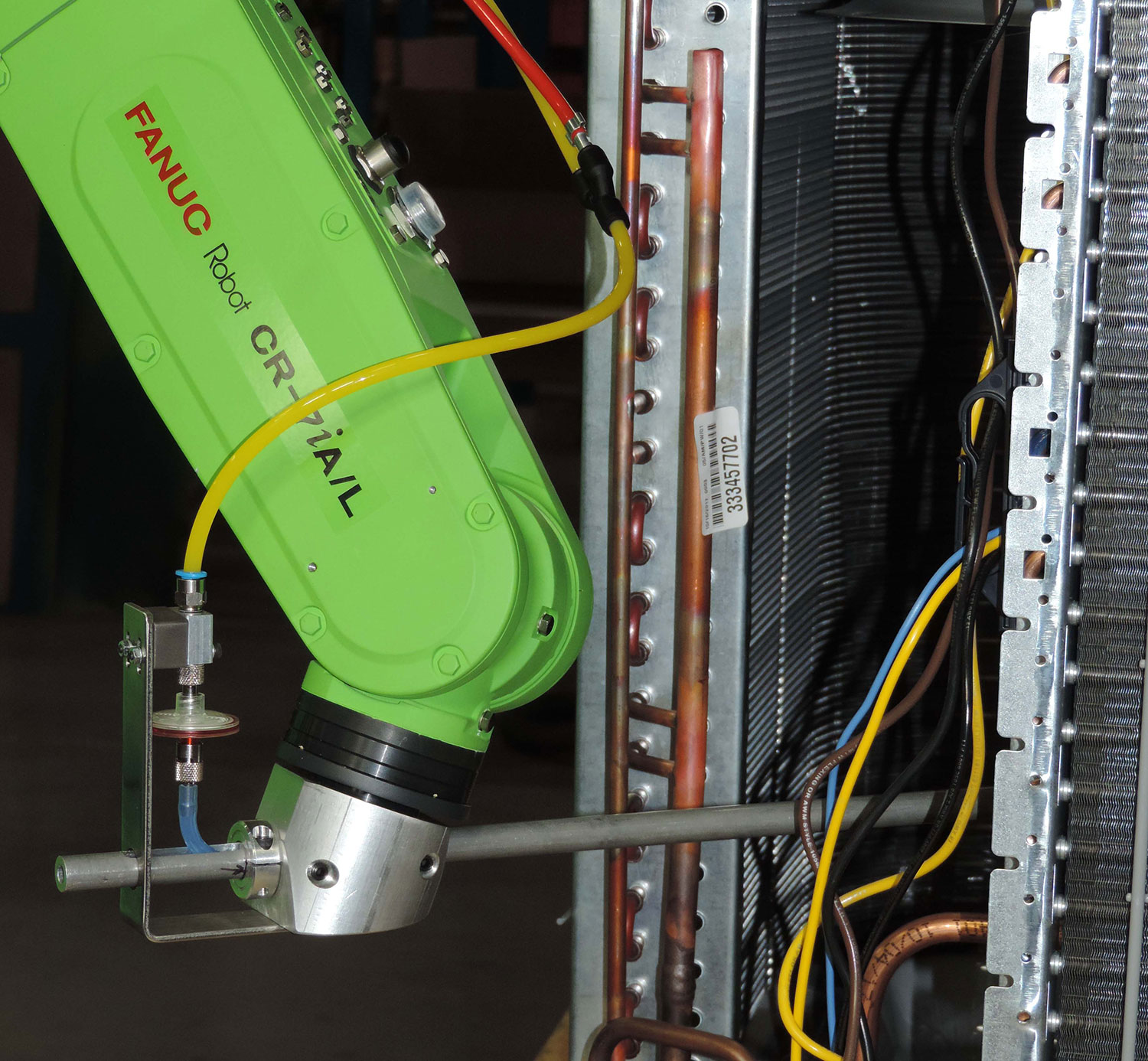

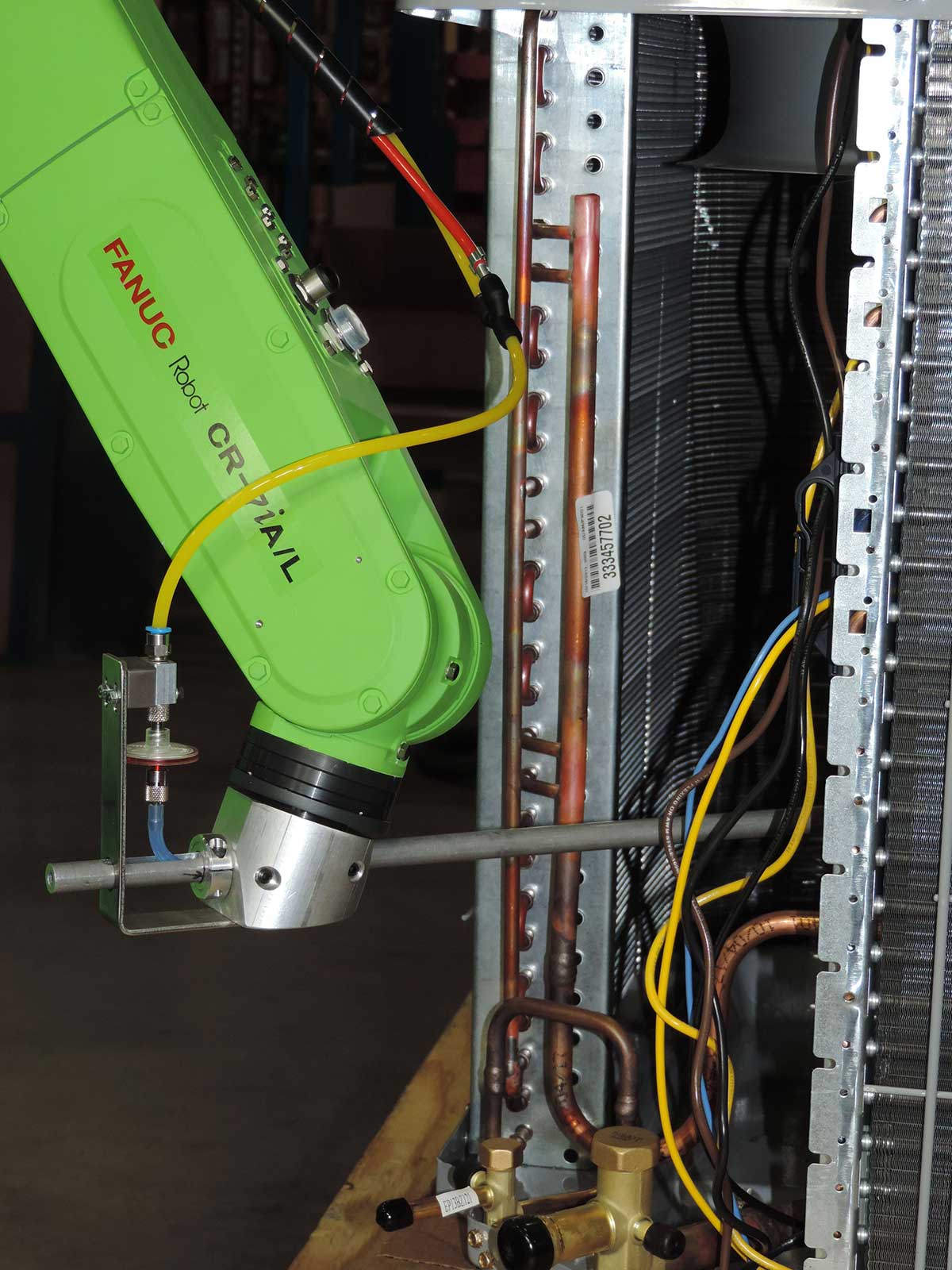

Remtec has targeted experience in the development of a variety of collaborative robot applications, using the industry’s best robotic technology.

Our standard collaborative robot advantages include:

- Safe collaboration

- Easy programming and handling

- Proven, repeatable, and reliable technology

- Intelligent features like vision

- Small controller/ small footprint design

- Full ANSI/RIA system risk assessments

Are you interested in learning more about collaborative robot applications? Contact us to discuss your project. We can assist you in developing a robotic automation solution that meets your needs, goals, and budget.

Collaborative Robotics FAQs

Collaborative robots are robots that work directly with people, providing integrated support for your human workforce. In some cases the robot works freely with the worker, in other cases the associate is protected.

Increased safety, easy programs and handling, proven, repeatable, reliable technology resulting in enhanced production, intelligent features like vision, and small controller/small footprint design are the main advantages in implementing a collaborative robot into industrial manufacturing automation.

Cobot is an abbreviated term for collaborative robot. A collaborative robot is built to interact with human workers in a common space. A traditional robot is designed to work autonomously and away from human contact.

Collaborative robots are not always fenceless, meaning their contact with humans can be limited, but in many cases the goal is to allow the operator to freely work with the robot.

Collaborative robot applications include four basic operations: 1) safety-rated monitored stop, 2) hand guiding, 3) speed and separation monitoring , and 4) power and force limiting by design.

Collaborative robots can actually promote worker health and safety by taking over tedious, repetitive tasks and some degree of lifting.