Five Automation Problems Commonly Solved with Robotic Integration

Many industrial manufacturing processes have been difficult to adapt to automation for a variety of reasons. A new generation of more sophisticated robotic technology is now overcoming many of those obstacles through robotic integration. In this post we will highlight five common automation problems that can be solved with advanced robotic technology and a robotic integration plan.

- The system must adapt to changing requirements and sizes.

Many operations require equipment and technologies to handle varying requirements from batch to batch. Robotic integration allows for flexibility to manage differently sized and shaped products. Robotic systems can be designed for quick and easy tooling changes for minimal downtime and peak efficiency.

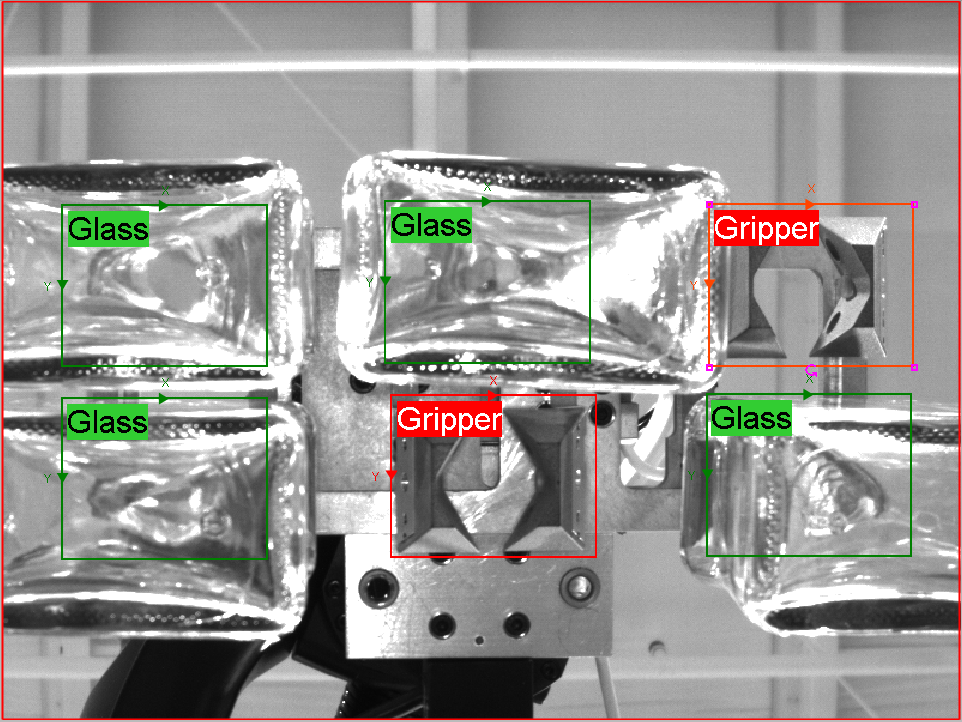

- The process must allow inspection for problems or changes.

Robotic vision inspection can be incorporated into virtually any robotic integration. These systems have become increasingly powerful and flexible, allowing inspection tasks to be integrated into robotic work cells. Robotic inspection systems offer substantial cost savings over traditional labor intensive inspection solutions. Since robotic vision inspection allows for the inspection of every part produced, quality in manufacturing improves.

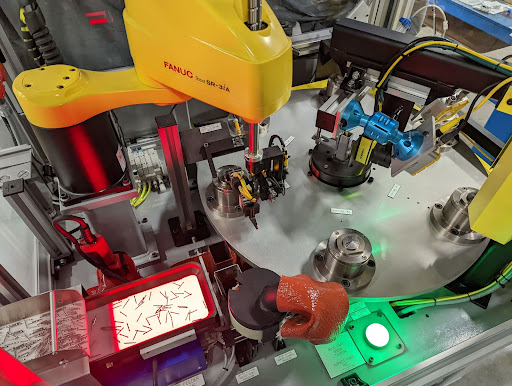

- People need to be able to work within the process.

Collaborative robots, or cobots, are flexible, lightweight robots that work with your human labor force. They are highly adaptable, with a small footprint, and easily deployed to different tasks. Additional safety equipment is often not needed, depending on the results of the risk assessment findings. They are equipped with an intuitive programming interface to make set up and implementation fast and easy. They are particularly well-suited for tasks such as pick and place.

- The system controls need to integrate with existing systems.

Today’s robotic technology allows new systems and legacy equipment to be controlled and production data can be collected, using one integrated control system, developed to work with your automated assembly process. It is all a matter of selecting a highly experienced robotic integration specialist to perform an analysis and design a system that seamlessly combines new technology with existing assets.

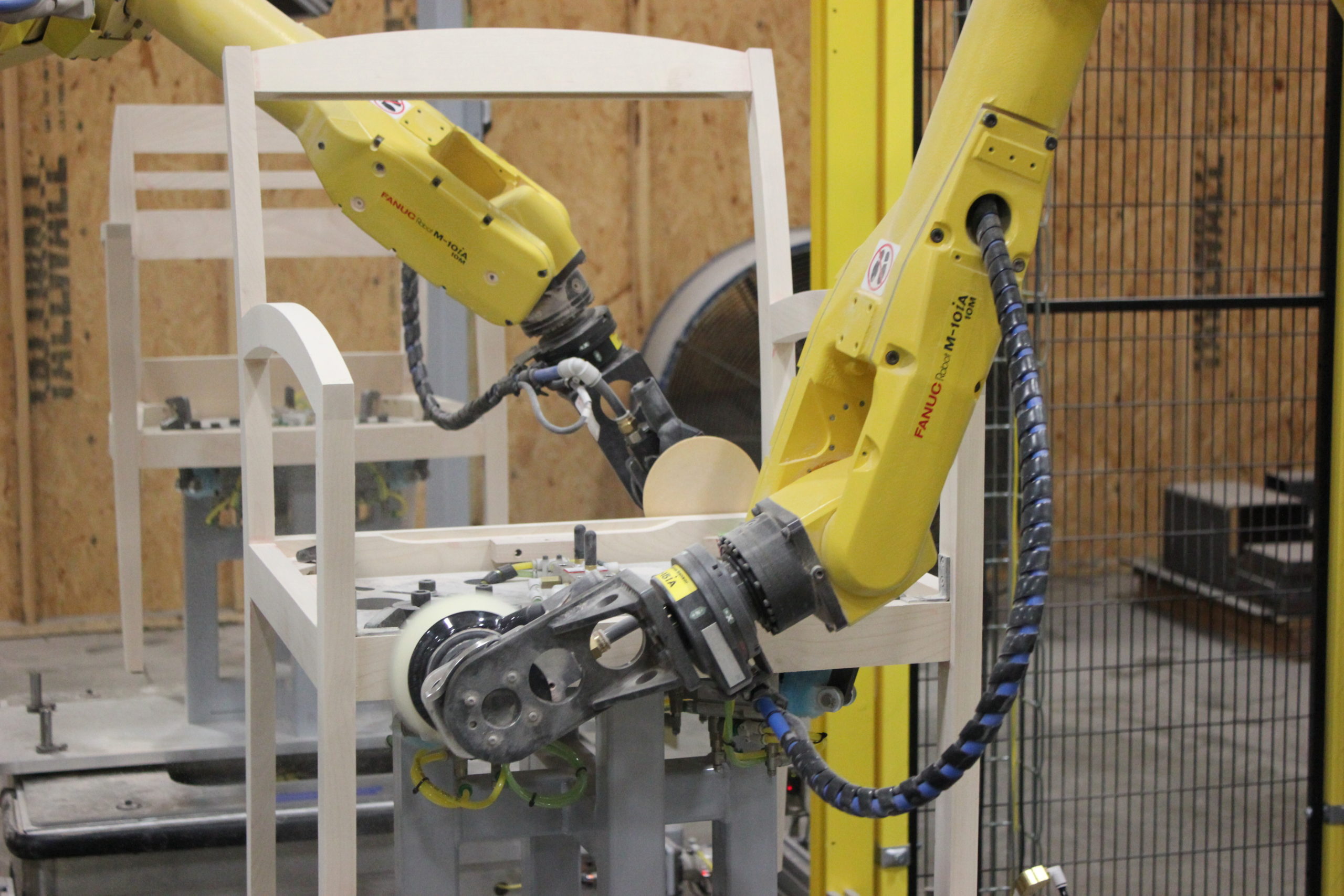

- Limited space is available for the system and process.

Robotic systems are not a one-size-fits-all proposition. Experienced robotic integration teams can select robots and design systems to fit the specific application and environment. Today’s robotic technology offers an extremely high degree of flexibility and space efficiency.

Our experience in robotic integration and robotic systems offers you a significant competitive advantage. Contact us to discuss how Remtec can help you advance your business.