Robotic Packaging Automation That Integrates With Your Production Line

Key Technical Capabilities:

- Cycle rates: Up to 100+ picks per minute per robot for standard applications

- Payload range: 1kg to 315kg depending on application and robot model

- Applications: Case packing, tray packing, blister pack handling, product sortation, palletizing

- Integration approach: Modular systems designed for phased implementation with 2-4 week installation windows

- Vision systems: Integrated 2D/3D vision for random bin picking, product orientation, and quality verification

Explore Our Integrated Systems

How Does Robotic Packaging Integrate With Existing Systems Without Causing Major Downtime?

The primary concern for plant managers evaluating automation is production disruption. Remtec’s approach minimizes downtime through modular, phased implementation that works around your production schedule.

Systems are pre-built and tested at our facility, then installed during scheduled maintenance windows or off-shifts. New systems can run alongside existing manual operations during validation, allowing gradual transition rather than hard cutover. Most projects are operational within 1-4 days from equipment arrival.

What Are the Real Costs and ROI Timeline for Mid-Size Manufacturing Plants?

Most mid-market manufacturers see payback within 6-36 months. Cost drivers include SKU variety, existing infrastructure compatibility, required cycle rates, and vision system complexity.

Operational improvements that drive ROI: labor reallocation from repetitive tasks to higher-value activities, consistent throughput that eliminates natural productivity decline in manual operations, reduced product damage from consistent handling, and extended operating hours with minimal supervision.

Hidden costs to consider: 1-2 days of staff training, preventive maintenance schedules, and potential facility modifications for electrical or safety systems.

What Proof Do I Have This Works in Facilities Like Ours?

S.S. White Technologies – Vertical Pouch Filling Automation

The Challenge: S.S. White needed to automate their vertical pouch packaging line to eliminate repetitive handling injuries and increase throughput for medical device components. Small, delicate parts required precise placement into pre-formed pouches moving on an intermittent moving web.

The Implementation: Fanuc SR-3iA scara robot with custom vacuum end-effector designed for part geometry. Vision-guided picking from vibratory feeders accommodated part orientation variability. Integration with existing Phoenix Quick Pouch vertical form fill and seal pouch packaging equipment. Single day installation, commissioning, and production start-up.

Results: Eliminated repetitive motion injuries from manual pouch loading. Achieved consistent 30+ picks per minute versus 10-20 with manual operators. Eliminated miss counted and misloaded pouches thru direct part placement sensing. Enabled staff redeployment to quality inspection and machine monitoring roles.

Hartz Mountain – Blister Pack Tracking System

The Challenge: Hartz Mountain needed to eliminate mispacks and improve traceability in their consumer product blister pack operations. Manual tracking was error-prone and couldn’t keep pace with production speed requirements.

The Implementation: Vision-guided robot system identified and tracked individual product tubes through the feeding system. Automated reject system for incorrect SKU and blister load confirmation greatly reduced quality slips.

Results: Vision system captured 100% of products versus statistical sampling in manual inspection. Eliminated human error in manual confirmation and data entry. The system reduced mispacks, greatly increased packaging line throughput, and enabled faster line speed adjustments based on real-time quality data.

Technical Specifications

Standard Fanuc Robot Models for Packaging

| Robot Model | Payload | Reach | Typical Application |

| Delta Series | 1-12 kg | 280-1600 mm | Pick and place, case, tray, pouch, and blister loading |

| SR Series | 3-20 kg | 400-1100 mm | Pick and place, case, tray, pouch, and blister loading |

| M-10 Series | 8-16 kg | 1103-2032 mm | Pick and place, case packing, small parts |

| M-20 Series | 12-35 kg | 1445-2272 mm | Case packing, tray loading |

| M-410 Series | 110-700 kg | 2403-3143 mm | Palletizing, heavy cases |

Safety & Compliance

- ANSI/RIA R15.06 compliant robotic work cells

- OSHA-compliant safety guarding and emergency stop systems

- UL certification as needed

Certified FANUC Integration for the East and Midwest

As a long-standing FANUC Authorized System Integrator, Remtec brings proven robotic expertise to manufacturers across the Midwest and Eastern U.S. Our team designs and installs reliable automation systems built around FANUC robots and vision technologies, ensuring smooth deployment, strong performance, and long-term support. For plants looking to modernize picking, packing, palletizing, or material handling, Remtec offers a partner with deep experience and a regional presence you can count on.

Frequently Asked Questions

Basic operation requires 1-2 days covering robot startup/shutdown, simple program adjustments, and first-level troubleshooting. Most production supervisors can learn pendant-based programming for routine modifications. Complex programming changes typically require engineering support.

Fanuc controllers store multiple programs for different products. If tooling changes are not required, changeovers can be as quick and simple as a push of a button. If manual tooling change is preferred, changeovers are designed to take less than 10 minutes. Adding new SKUs can take as little as 10-60 minutes—teaching new pick points, adjusting vision parameters, and adjusting end-of-arm tooling. For high SKU variety, we design flexible gripper systems with vision-guided operation.

Remote diagnostics resolve many issues within hours. For hardware failures requiring on-site service, standard support provides next-business-day response, and replacement part delivery times vary.

Yes. Robots handle high-volume, repetitive tasks while manual operators manage exceptions, changeovers, and lower-volume SKUs. This provides flexibility while capturing automation benefits on highest-volume products.

All installations include comprehensive safety systems: physical guarding, light curtains, area scanners, and emergency stops. We follow the latest ANSI/RIA R15.06 standards and provide complete safety risk assessments during the project.

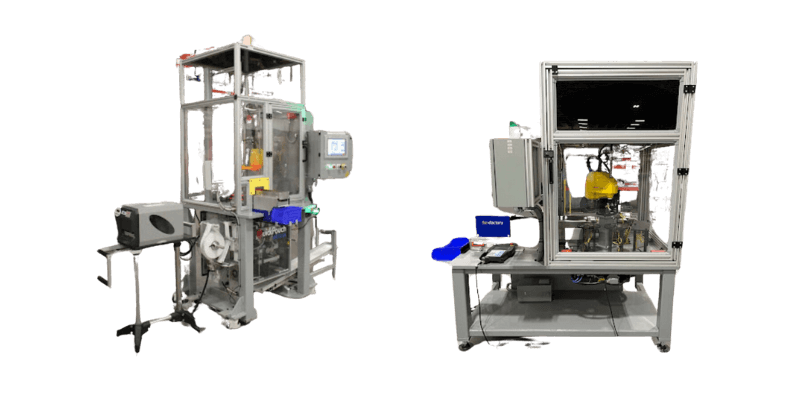

Case Study: S.S. White Technologies Vertical Pouch Process Benefits from Robotic Automation

Offering maximum flexibility, these robotic high speed picking systems provide the customer with the ability to change SKUs automatically on demand.

LEARN MORE

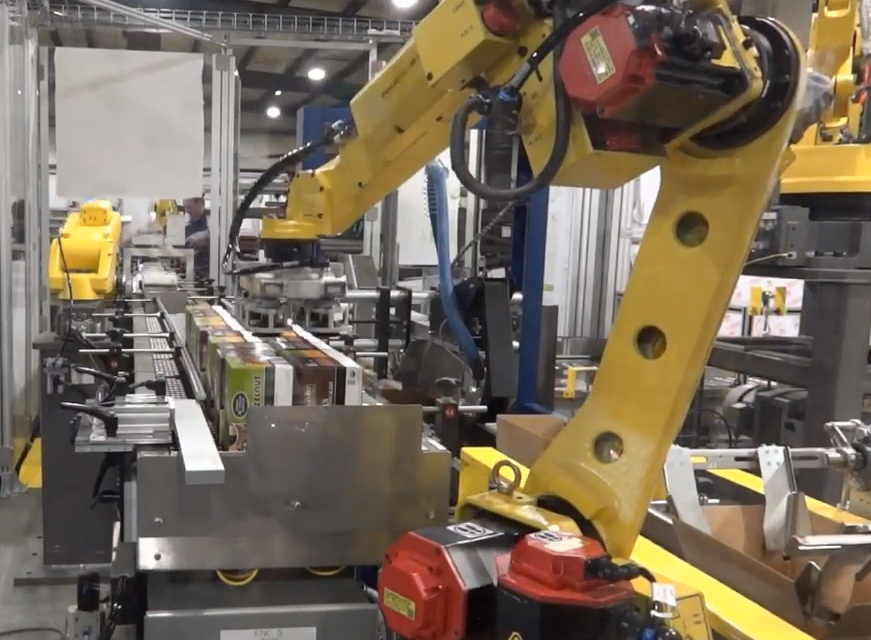

Case Study: Hartz Mountain Blister Packing Process Benefits from Robotic Automation

A customized picking robot system was designed with a high speed, 6-axis articulated robot and two SCARA robots, as well as machine vision and high speed line tracking.

LEARN MORE