Robotic Assembly

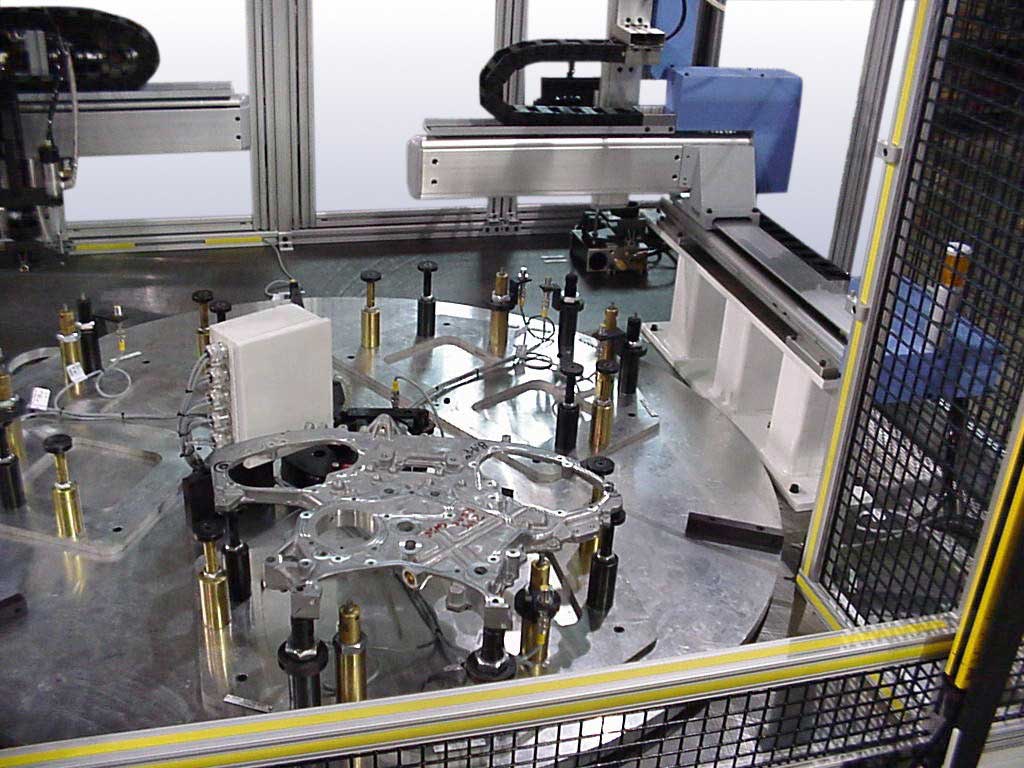

Industrial manufacturers are realizing the significant cost savings, quality improvements, and productivity gains associated with flexible robotic assembly. Robotic assembly systems can consist of one or multiple assembly operations occurring within a work cell. Common robotic assembly applications include such functions as:

- Part fastening

- Part joining

- Part sorting

- Part identification

- Part feeding

- Tool changing

- Part inspection

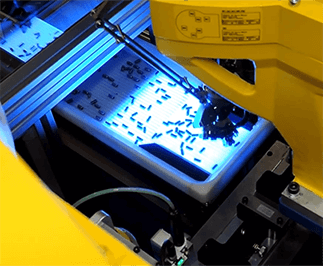

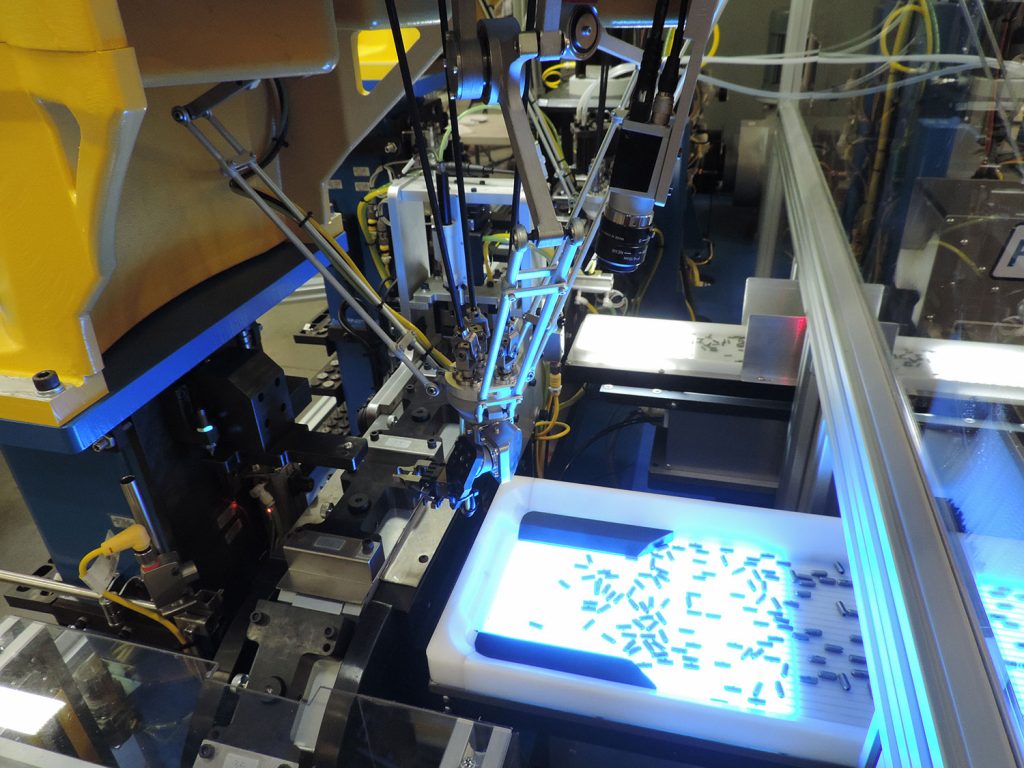

- Bin picking

- Part traceability

- Adhesive, sealant and grease dispensing

As one of the leading robotic integrators in North America, Remtec has assisted a wide range of manufacturing organizations to realize the benefits of robotic assembly in their industrial processes.

Explore Our Integrated Systems

New systems and legacy equipment can be controlled and production data can be collected, using one integrated control system, developed to work with your automated assembly process.

Our experience in designing robotic assembly systems offers you an unbeatable competitive advantage. Contact us to discuss how Remtec robotic assembly can help you advance your business.

Robotic Assembly FAQs

Remtec is one of the leading robotic integrators in North America, having developed robotic assembly systems for a wide range of manufacturing operations.

Robotic assembly systems can consist of one or multiple assembly operations occurring within a work cell.

Remtec specialists will work with you to evaluate your existing production process to get the most from existing assets and manual efforts, while integrating the latest robotic assembly technology.

New systems and legacy equipment can be controlled and production data can be collected, using one integrated control system, developed to work with your automated assembly process.

Assembly robots can fasten, join, sort, identify, feed, inspect, and trace parts. They can also change tooling, do bin picking, and also dispense adhesive, sealant, or grease.

Remtec assembly robot solutions have helped manufacturers achieve significant cost savings, quality improvements and productivity gains.