Benefits of Robotic Assembly in the Industrial Process

Early skepticism regarding the adoption of in the industrial manufacturing environment is fading as more businesses are realizing the significant cost savings, quality improvements, and productivity gains associated with flexible robotic solutions.

Advantages of automating assembly with robotics include:

- Improved labor productivity

- Reduction in cycle time and floor space utilization

- Quality and reliability improvement

- Consistency in processing

- Reduction of waste

- Lower production costs

Operating faster and with more precision than human labor, assembly robots perform highly repetitive tasks, freeing your employees to perform other tasks that do not involve risk for workplace injuries. Robotic assembly systems may consist of one or multiple assembly operations occurring within a work cell. Integrating automated robots into a workplace generally requires a high initial investment, but the ROI time is minimal.

Common robotic assembly applications include functions such as:

- part fastening

- part joining

- part sorting

- part identification

- part feeding

- tool changing

- part inspection

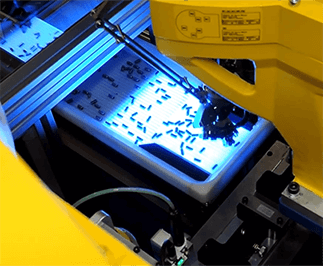

- bin picking

- part traceability

- adhesive, sealant & grease dispensing

Collaboration of robots and humans is also becoming a popular option for industrial manufacturing assembly. Lower in cost and with a smaller footprint, collaborative robots with advanced vision and sensor technologies are allowing business owners to support their human labor with robotic assistance. In the event that an employee gets in the way of a robot on the production line, the robot will stop until its path is clear.

Remtec has helped a wide variety of manufacturers realize the benefits of robotic assembly in their industrial processes. Our team of experienced robotic specialists evaluate existing production processes to make the most of existing assets and manual labor, while integrating the latest robotic assembly technology to move operations to an enhanced level of productivity.

Assisted by the latest analysis and simulation technology, Remtec will design your robotic assembly processes. Our experienced robotic integrators will develop, deliver, and install a complete robotic assembly system in your plant. New systems and legacy equipment can be controlled and production data can be collected, using one integrated control system, developed to work with your automated assembly process.

As one of the leading robotic integrators in North America, Remtec is highly experienced in robotic assembly system design. Contact us to discuss how Remtec robotic assembly can help you advance your business.