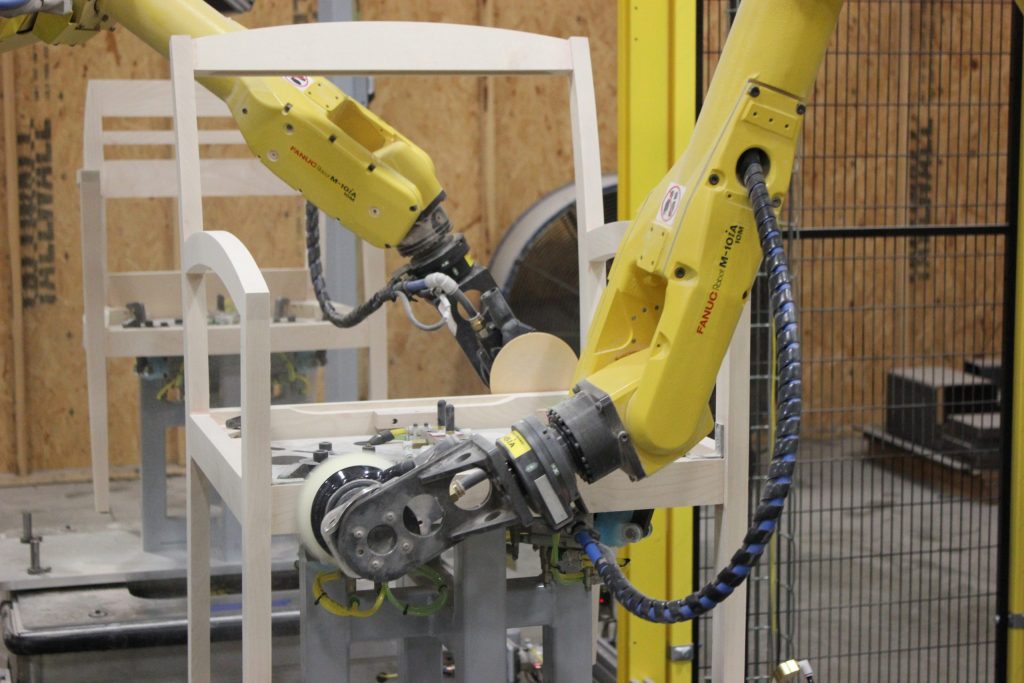

Common Robotic Integration Challenges and Solutions

Compatability & Connectivity

A significant challenge in robotic integration is ensuring seamless compatibility with existing systems. Robots must work in harmony with current machinery, software, and network infrastructures, which often requires overcoming data integration and connectivity hurdles.

- Data Integration: Many organizations use legacy systems with limited data-sharing capabilities, making it difficult to synchronize robotic systems.

- Connectivity: Robust connectivity, such as through IoT (Internet of Things) technology, is essential for real-time data flow and coordination between robotic systems and other components. Connectivity issues can lead to disruptions and inefficiencies.

- Adopting middleware solutions can bridge compatibility gaps between new robotic systems and legacy infrastructure.

- Investing in open-platform architectures ensures future scalability and easier integration with diverse technologies.

- Conducting pilot programs helps identify integration bottlenecks before full deployment.

Workforce Training & Adaptation

Introducing robotics disrupts traditional workflows, requiring employees to adapt to new roles and technologies. Without proper training, workers may struggle to operate or collaborate effectively with robots, leading to inefficiencies and resistance.

- Skill Gaps: Employees may lack the technical expertise needed to program or troubleshoot robotic systems.

- Resistance to Change: Workers may fear job displacement or view robotics as a threat to their roles, resulting in reduced morale.

- Develop comprehensive training programs tailored to different roles, such as technicians, operators, and managers.

- Foster a culture of collaboration by demonstrating how robotics can enhance productivity and reduce repetitive tasks, allowing focus on higher-value activities.

- Establish clear communication channels to address employee concerns and provide reassurance about job security.

- Simplify machine interface requirements to ease the burden on associates.

Maintenance & Reliability Concerns

Robotic systems, while designed for precision, are not immune to wear and tear. Maintenance challenges include ensuring uptime, managing parts replacement, and addressing unforeseen failures. Reliability concerns can hinder productivity and increase operational costs.

- Predictive Maintenance: Many organizations still rely on reactive maintenance approaches, addressing issues only after a failure occurs. This approach can lead to unexpected downtime.

- Component Durability: The durability of robotic components, especially in harsh environments, is a recurring concern. For instance, robots operating in chemical plants or extreme temperatures may experience accelerated wear.

- Implement predictive maintenance strategies using Industry 4.0 practices and IoT sensors to monitor robotic health (like Fanuc’s ZDT solution) and anticipate failures before they occur.

- Establish regular maintenance schedules and invest in high-quality spare parts to minimize downtime.

- Collaborate with manufacturers to ensure customizations that enhance durability in challenging operating conditions.

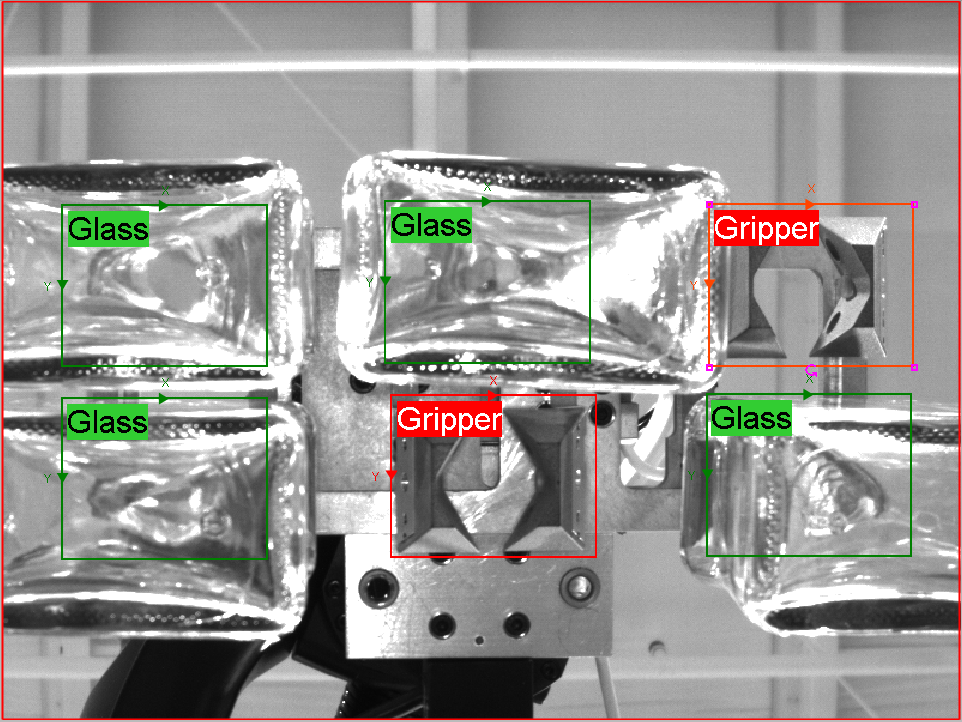

Safety & Compliance Challenges

Ensuring the safety of workers and compliance with regulatory standards is paramount in robotic integration. Robots, especially autonomous systems, can pose risks if safety protocols are not rigorously implemented.

- Human-Robot Interaction Risks: Close proximity operations increase the risk of collisions or accidents.

- Compliance Requirements: Regulatory bodies such as RIA, ANSI, OSHA and ISO define specific safety standards for robotic operations and hazard assessments. Failing to meet these standards can result in fines, legal complications, and/or injuries.

- Equip robots with advanced safety features, such as safety sensors and Fanuc DCS (Dual Check Safety), to prevent accidents during human-robot interactions.

- Conduct risk assessments and adhere to global standards such as RIA’s foundational standard 15.06-2012 (and subsequent additions), ISO 10218 for industrial robots and ISO/TS 15066 for cobots.

- Provide employees with thorough safety training to ensure awareness of robotic operations and emergency procedures.

Conclusion

Integrating robotics into industrial settings offers transformative benefits but is not without challenges. Addressing technical compatibility, equipping the workforce with necessary skills, ensuring reliable operation, and adhering to safety and compliance requirements are critical for successful implementation. By proactively tackling these obstacles with strategic solutions, organizations can unlock the full potential of robotic technology while ensuring smooth transitions and sustainable growth.