The True Cost of Manual Picking in Your Manufacturing Cell

Overview Summary Manual picking costs far more than hourly wages due to fatigue, turnover, and injury risk Small picking errors often create major downstream quality issues and rework Manual picking frequently becomes the throughput ceiling for the entire production line Changeovers and SKU variability amplify delays in high-mix environments These costs are scattered across departments, … Continued

How to Automate High-Mix Part Picking Without Losing Flexibility

Overview Summary High-mix plants often struggle with slow changeovers, manual sorting, and production bottlenecks. Traditional robots require reprogramming for every SKU, making them impractical for variable, short-run work. Vision-guided robots now identify parts in real time and adapt automatically to SKU changes. Recipe-based changeovers eliminate reteaching and reduce operator skill requirements. Plants can increase throughput, … Continued

Collaborative vs. Industrial Palletizing Robots: When to Choose Speed Over Flexibility

When you’re evaluating palletizing automation, the first decision isn’t whether to automate—it’s which robot architecture fits your production reality. Collaborative robots promise flexibility and easy deployment, but industrial palletizers deliver the speed and payload capacity that keep high-volume lines running. The wrong choice means either overspending on capability you don’t need or underperforming against your … Continued

Meeting Robotic Integration Challenges: Safety and Compliance

Successful robotic integration is not only about enhancing productivity and efficiency, it’s also about keeping employees safe. This means ensuring every system operates in accordance with the latest regulatory standards. As industrial robotics technology continues to advance, so do the requirements for safety compliance that are designed to protect workers and operations. Adapting to Updated … Continued

Meeting Robotic Integration Challenges: Maintenance and Reliability Concerns

Robotic integration has become more accepted in today’s industrial and manufacturing processes due to increased efficiency, precision, and operational speed. However, as companies adopt these advanced systems, they encounter maintenance and reliability challenges that can impact productivity and cost-effectiveness. Seamless robotic performance requires strategic planning, preventive maintenance, and leveraging emerging technologies to address potential issues … Continued

Adapting the Workforce: Training for Automation in Modern Manufacturing

In today’s rapidly evolving manufacturing landscape, the integration of automation technologies is reshaping operations and redefining workforce roles. As automation becomes increasingly prevalent, the need for effective workforce training and adaptation has never been more critical. This blog explores the significance of equipping employees with the necessary skills to thrive alongside advanced technologies, the challenges … Continued

Meeting Robotic Integration Challenges: Compatibility and Connectivity

A wide range of industries are transforming operations with robotic systems that offer the benefits of enhanced efficiency, precision, and productivity. While the adoption of robotics offers significant advantages, integrating robotics into existing infrastructures can also present serious challenges. This blog post is the first in a series that will explore some of the most … Continued

The Financial Benefits of Implementing Robotic Palletizing

When considering ways to improve the efficiency and profitability of your business, have you examined your palletizing operations? While traditional manual palletizing methods tend to be labor-intensive, prone to error and often lead to workplace injuries, robotic palletizing solutions offer a compelling alternative. Read on as we explore the drawbacks of conventional palletizing methods and … Continued

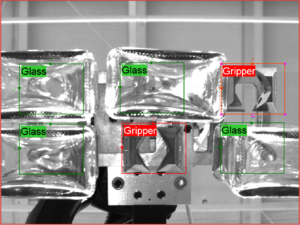

Six Reasons to Choose a Certified Vision Specialist for Your Machine Vision Integrator

In today’s rapidly evolving technology-driven workplace, machine vision has become increasingly advantageous across a wide range of industries. From quality control in manufacturing to autonomous vehicles and medical imaging, machine vision systems play an essential role in enhancing efficiency, accuracy, and productivity.

The successful implementation of such systems hinges upon partnering with the right integrator, preferably a Certified Vision Specialist.

3 Ways that Cobots Work in Material Handling & Process Applications

The integration of automation has become indispensable. Cobots, or collaborative robots, have emerged as a game-changer, particularly in material handling and process applications. These versatile machines work alongside human workers, enhancing efficiency, safety, and productivity. Read on to take a look at three key ways cobots are reshaping these sectors: vision inspection, dispensing, and palletizing.