Currently browsing Pick and Place Robots

The True Cost of Manual Picking in Your Manufacturing Cell

Overview Summary Manual picking costs far more than hourly wages due to fatigue, turnover, and injury risk Small picking errors often create major downstream quality issues and rework Manual picking frequently becomes the throughput ceiling for the entire production line Changeovers and SKU variability amplify delays in high-mix environments These costs are scattered across departments, … Continued

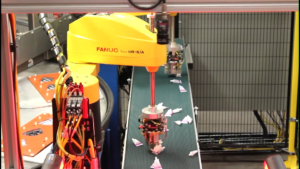

How to Automate High-Mix Part Picking Without Losing Flexibility

Overview Summary High-mix plants often struggle with slow changeovers, manual sorting, and production bottlenecks. Traditional robots require reprogramming for every SKU, making them impractical for variable, short-run work. Vision-guided robots now identify parts in real time and adapt automatically to SKU changes. Recipe-based changeovers eliminate reteaching and reduce operator skill requirements. Plants can increase throughput, … Continued