Meeting Robotic Integration Challenges: Compatibility and Connectivity

A wide range of industries are transforming operations with robotic systems that offer the benefits of enhanced efficiency, precision, and productivity. While the adoption of robotics offers significant advantages, integrating robotics into existing infrastructures can also present serious challenges.

A wide range of industries are transforming operations with robotic systems that offer the benefits of enhanced efficiency, precision, and productivity. While the adoption of robotics offers significant advantages, integrating robotics into existing infrastructures can also present serious challenges.

This blog post is the first in a series that will explore some of the most common critical challenges we see in robotic integration and consider potential solutions.

Technical Compatibility

A significant challenge in robotic integration is ensuring seamless compatibility with existing systems. Robots must work in concert with current machinery, software, and network infrastructures, which often involves overcoming data integration and connectivity hurdles. Robotic systems commonly need to integrate with system structures such as:

- Existing industrial equipment

- Manufacturing execution systems (MES)

- Enterprise resource planning (ERP) systems

They frequently use diverse communication protocols, data formats, and programming languages. Achieving seamless communication can require extensive middleware development or the adoption of standardized protocols.

Real-Time Data Requirements

Many robotic applications, such as assembly lines or quality inspections, demand real-time data processing and decision-making. Integrating robots with existing real-time control systems is complex due to latency and synchronization issues.

A key challenge is ensuring that data flows between the robot and control systems without delays that could disrupt operations and affect overall line throughput.

Data Security and Integrity

Robotic systems generate and exchange sensitive data, such as production metrics, diagnostics, and operational parameters. Ensuring data integrity and secure transmission is critical but challenging, especially when multiple systems or networks are involved. Any data corruption or breach can lead to operational inefficiencies or compliance violations.

Data Overload and Management

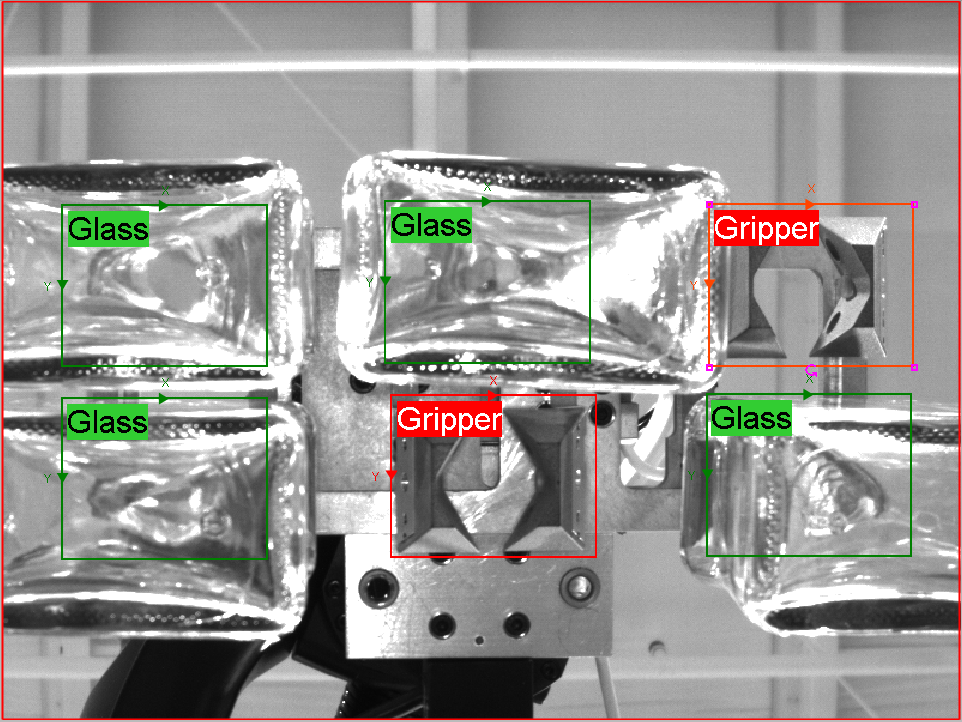

Today’s robotic systems are equipped with advanced sub-systems and sensors that generate vast amounts of data, including images, real-time motion/path adjustments, and performance metrics. Integrating, storing, and processing this data within legacy IT infrastructure can strain resources.

Organizations may need to upgrade to scalable cloud or edge computing solutions to handle the increased data loads as a part of their automation programs.

Technical Connectivity Challenges

Robots typically rely on industrial communication networks like Ethernet/IP to connect with control systems and other equipment. Compatibility issues arise when the existing network infrastructure does not support the robot’s communication requirements.

Latency and Reliability

For tasks like precision assembly, in station welding, or real-time inspection, even minor network delays can lead to performance issues. Connectivity reliability becomes especially challenging in environments with high electromagnetic interference, such as manufacturing floors. Balancing the need for low latency with interference-resistant connectivity solutions is a key challenge.

Integration with IoT Ecosystems

A newer generation of robotics often leverages IoT (Internet of Things) technologies for predictive maintenance, remote monitoring, and performance optimization. Integrating robots with IoT platforms can be difficult if the existing IoT infrastructure lacks compatibility with newer robotic systems. Ensuring that a robot’s data can seamlessly feed into IoT analytics platforms without losing fidelity or context can be an issue.

Cybersecurity Risks

As robots connect to more expansive industrial networks and external systems, vulnerability to cybersecurity threats increases. Unauthorized access to robotic control systems can lead to data theft, equipment damage, or operational disruptions. Using encryption, firewalls, and secure authentication methods for all connected devices is a must. Fanuc’s new R-50iA controller also adds enhanced cyber security features that provide multiple layers of defense to secure data exchange, whether it’s remote access, file transfers, or web communication.

Best Practices for Addressing Robotic Compatibility and Connectivity Challenges

- Adopt Standardized Protocols – Use universal communication standards like OPC UA or MQTT to facilitate data exchange between diverse systems.

- Leverage Middleware – Implement middleware solutions to bridge gaps between incompatible systems and enable smooth data integration.

- Plan for Scalability – Design networks and data architectures to handle future demands, including increased data generation from robots.

- Focus on Cybersecurity – Implement strong encryption, access control, and real-time monitoring to secure data and connectivity.

- Perform Thorough Testing – Conduct integration tests in simulated environments to identify and resolve compatibility issues before deployment.

Remtec’s experienced team of engineers is here to assist you with your robotic integration challenges. We will evaluate your existing production process to get the most from existing assets while integrating the latest technologies to move your operation to the next level. Contact us to discuss how Remtec can help you advance your business through robotic automation.