Meeting Robotic Integration Challenges: Maintenance and Reliability Concerns

Robotic integration has become more accepted in today’s industrial and manufacturing processes due to increased efficiency, precision, and operational speed. However, as companies adopt these advanced systems, they encounter maintenance and reliability challenges that can impact productivity and cost-effectiveness. Seamless robotic performance requires strategic planning, preventive maintenance, and leveraging emerging technologies to address potential issues before they escalate. Understanding this before integration greatly increases the likelihood of application success.

Robotic integration has become more accepted in today’s industrial and manufacturing processes due to increased efficiency, precision, and operational speed. However, as companies adopt these advanced systems, they encounter maintenance and reliability challenges that can impact productivity and cost-effectiveness. Seamless robotic performance requires strategic planning, preventive maintenance, and leveraging emerging technologies to address potential issues before they escalate. Understanding this before integration greatly increases the likelihood of application success.

In the third installment of our series, we explore the key challenges involved in maintaining robotic systems and provide practical solutions for improving reliability and maximizing uptime.

Robotic Maintenance Challenges

Complexity and Specialized Knowledge

Unlike traditional machinery, robotic systems require specialized expertise for proper maintenance and troubleshooting. Many factories do not have employees with robotic experience and skills, leading to prolonged downtimes when issues arise.

Solution: Manufacturers can invest in robotics training programs for technicians and establish partnerships with vendors who offer maintenance support.

Frequent Maintenance and Downtime Risks

Industrial robots are subjected to constant motion, friction, and load stress, leading to regular wear and tear. If not maintained proactively, unexpected failures can result in significant downtime and production delays.

Solution: Implement a predictive maintenance strategy that utilizes IoT and AI-driven monitoring to detect anomalies before failures occur.

Cost of Unplanned Downtime

Every minute that your production line is down due to robotic failure translates to lost revenue. Without a well-defined maintenance schedule, manufacturers risk unexpected breakdowns that disrupt operations.

Solution: Establish a preventative maintenance routine and schedule routine inspections to reduce emergency repairs.

Reliability Concerns in Industrial Robotics

Wear and Tear on Components

Industrial robots operate in harsh environments, leading to degradation of mechanical parts over time. If not replaced on time, these components can cause system failures.

Solution: Develop a spare parts inventory and replace worn-out parts before they compromise performance.

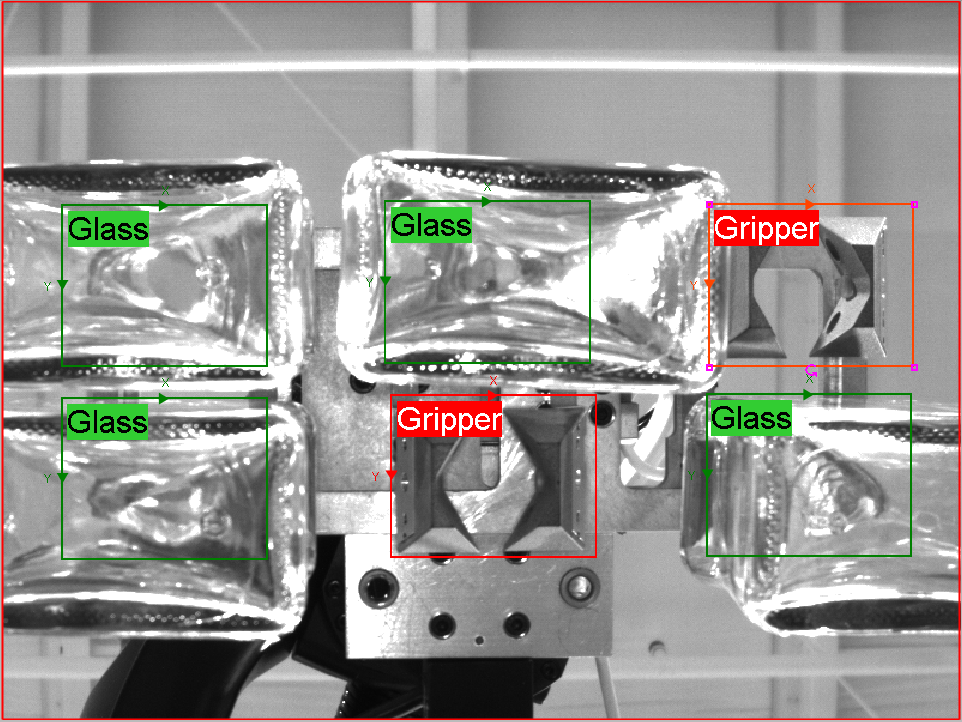

Software Malfunctions and Integration Challenges

The newest generation of robotic systems rely on software algorithms and possibly machine learning for autonomous decision-making. However, software bugs, outdated firmware, or integration issues with other automation systems can reduce efficiency.

Solution: Regularly update robotic software and firmware while ensuring seamless integration with factory automation systems.

Lack of Real-Time Monitoring

Without continuous monitoring, minor inefficiencies can go unnoticed, leading to larger failures.

Solution: Implement real-time diagnostics and AI-driven monitoring to track robot health and performance 24/7.

Maintenance and Reliability Challenge Checklist

Implement a Predictive Maintenance Strategy

- Utilize machine learning and IoT sensors to predict failures before they occur.

- Reduce unplanned downtime and optimize maintenance schedules.

Invest in Technician Training

- Train in-house technicians to diagnose and troubleshoot robotic issues.

- Encourage partnerships with robotic vendors for maintenance support.

Leverage AI-Driven Monitoring Systems

- Install AI-based real-time monitoring tools for proactive issue detection.

Keep Software Updated and Build a Parts Inventory

- Keep robotic software up to date for optimal performance and security.

- Stock essential replacement parts to minimize repair delays.

Future-Proofing Your Robotic Systems

Future trends in robotic maintenance and reliability are developing rapidly, as more businesses of all types adopt this type of automation. Areas include:

- AI-Powered Self-Healing Systems – Future robots may be equipped with self-repair mechanisms powered by artificial intelligence.

- Cloud-Based Predictive Maintenance – Robots will integrate with cloud computing for enhanced data analysis and proactive maintenance scheduling.

Meeting the challenges of maintenance and reliability in industrial robotics requires proactive strategies. If you’re looking for expert guidance on optimizing your robotic maintenance strategy, The experienced Remtec team is here to assist. We specialize in cutting-edge industrial robotics solutions designed for long-term reliability and performance. Contact us to discuss your robotic integration goals.