The True Cost of Manual Picking in Your Manufacturing Cell

Overview Summary

- Manual picking costs far more than hourly wages due to fatigue, turnover, and injury risk

- Small picking errors often create major downstream quality issues and rework

- Manual picking frequently becomes the throughput ceiling for the entire production line

- Changeovers and SKU variability amplify delays in high-mix environments

- These costs are scattered across departments, making them hard to quantify

- Automating repetitive picking stabilizes output, improves quality, and frees skilled labor

Manual picking often feels like the safest option on the plant floor. It is familiar, flexible, and usually does not require a capital request. On paper, it looks cost efficient, but in practice, manual picking is often one of the most expensive process decisions being made inside a manufacturing cell.

The true cost is not limited to wages. It shows up quietly in:

- decreased throughput

- quality issues that surface downstream

- skilled people being taken away from higher-value work

Because these impacts are spread across labor, quality, and operations, they are easy to miss and easy to underestimate.

Labor Costs Involve More Than an Hourly Rate

Manual picking ties performance directly to human endurance and availability.

Fatigue Reduces Output Over Time

Repetitive picking and part orientation take a physical toll over the course of a shift. Cycle times gradually drift. Small pauses become more frequent. By the end of the day, the same task produces fewer parts than it did at the start.

This variability is rarely tracked, despite the fact that it directly affects daily output and schedule reliability.

Turnover Quietly Resets Productivity

Picking roles often experience higher turnover than other positions. Every new hire brings training time, supervision demands, and a learning curve that reduces output for weeks.

In high-mix cells, the burden is even heavier. Operators must remember part variations, orientations, and handling nuances that are difficult to fully document. Each staffing change resets that team knowledge.

Injuries Carry Long-Term Costs

Repetitive motion injuries rarely affect just one operator. They lead to overtime, temporary staffing, retraining, and schedule disruption. These costs often exceed the wage of the original position, and the impacts ripple throughout maintenance, supervision, and production planning.

Quality Costs: Errors That Travel Downstream

Manual picking introduces variation before parts ever reach the next process.

Mis-Picks Rarely Fail Immediately

A part placed backwards or slightly misaligned may not cause an immediate issue. Instead, it often shows up later as a jam, reject, or fault further down the line, where recovery takes longer and affects more equipment.

Downstream quality problems are frequently traced back to upstream manual handling.

Visual Inspection Is Inherently Inconsistent

Human inspection depends on lighting, experience, and fatigue. Two operators can make different decisions on the same part. That inconsistency forces tighter supervision and still does not eliminate escapes.

Rework Compounds Faster Than Expected

Even a small error rate at the picking stage can create a disproportionate amount of rework later. The labor spent correcting mistakes often rivals or exceeds the labor spent picking the parts in the first place.

Throughput Losses Hiding in Plain Sight

Manual picking frequently sets the pace for the entire manufacturing cell.

The Line Can Only Move as Fast as the Picker

Even when downstream equipment is capable of higher speeds, manual picking caps output. Robots wait. Conveyors back up. Capacity goes unused.

In many cells, automation investments fail to deliver expected ROI because upstream manual picking was never addressed.

Changeovers Add Up Quickly

In high-mix environments, switching SKUs means operators resetting habits, tools, and instructions. Minutes lost during each changeover add up to hours of lost production every week.

Delays Trigger Chain Reactions

When picking falls behind, buffers fill, machines idle, and supervisors step in to manage symptoms instead of improving flow. The entire cell becomes reactive rather than controlled.

Why Manual Picking Costs Are Easy to Miss

Manual picking costs are scattered across the organization:

- Overtime in one department

- Scrap in another

- A quality issue later in the shift

- Training time quietly absorbed

- Missed production targets explained as “normal variation”

No single line item captures the full impact, so the true costs stay hidden.

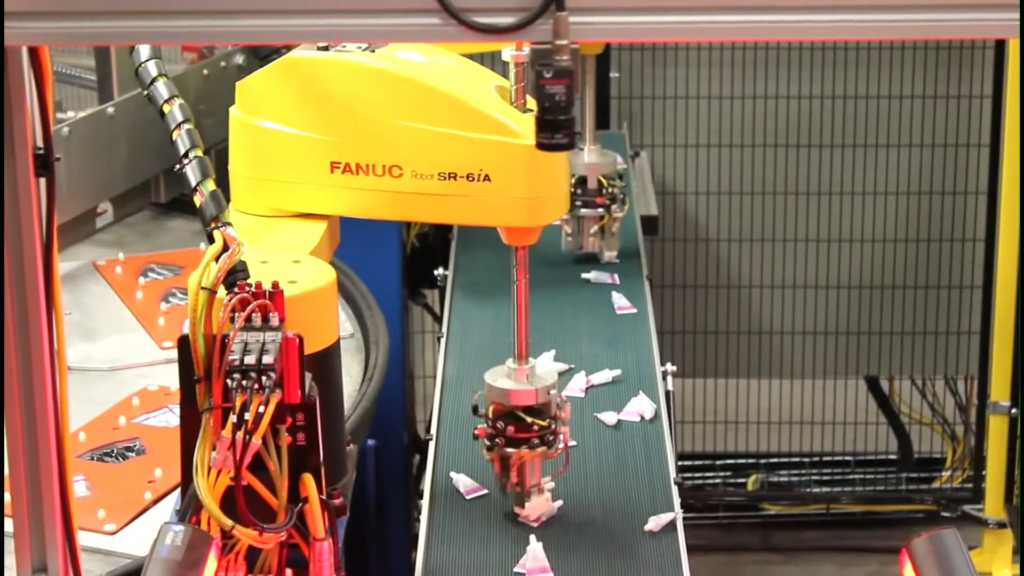

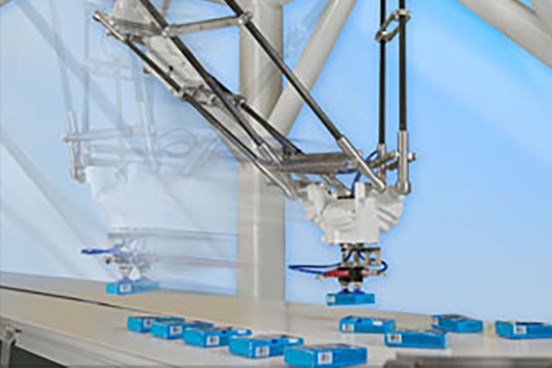

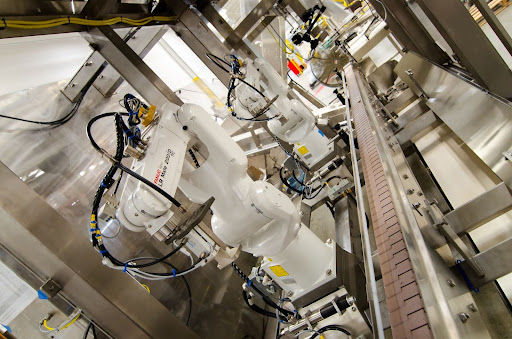

How Automation Optimizes Picking Operations

When repetitive picking and part orientation move to automation, several improvements appear quickly:

- Cycle times stabilize across shifts

- Output becomes predictable

- Quality improves through consistent handling

- Ergonomic risk is reduced

- Skilled operators are freed for higher-value work

- Capacity increases without adding headcount

An automated system with picking robots does not decrease flexibility. In many cases, it actually restores flexibility by removing the variability that manual work introduces, especially in high-mix environments.

Remtec Helps Manufacturers Reduce Hidden Picking Costs

Remtec Engineering designs and integrates flexible automation solutions that replace repetitive manual picking without sacrificing adaptability. By combining robotics, vision systems, and thoughtful cell design, Remtec helps manufacturers stabilize throughput, improve quality, and make better use of skilled labor, even in high-mix environments.

If you are evaluating where automation can deliver the fastest operational payoff, picking is often the best place to start.

Contact Remtec Engineering to discuss your manufacturing cell and explore practical automation options that fit your process.