Remtec Designs Robotic Flexible Part Feeding System for Dental Burs

FANUC SCARA Robots Ideal for High-Speed Pick and Placement of Small Parts

Remtec offers the ideal solution for pick and placement of small parts in high-speed applications. Remtec Automation is an industry leader in the design, build, integration, and service of secondary packaging and material handling automation solutions. We are also a FANUC Authorized System Integrator.

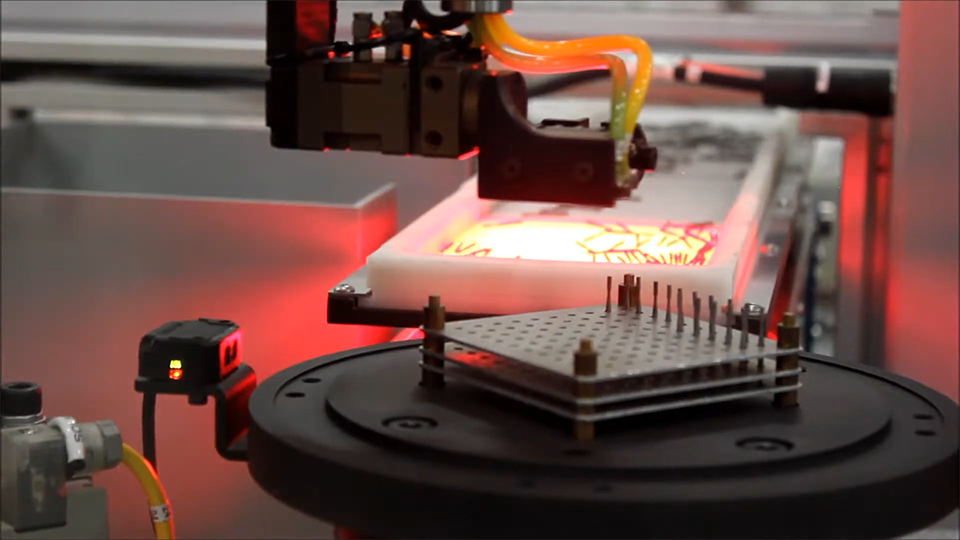

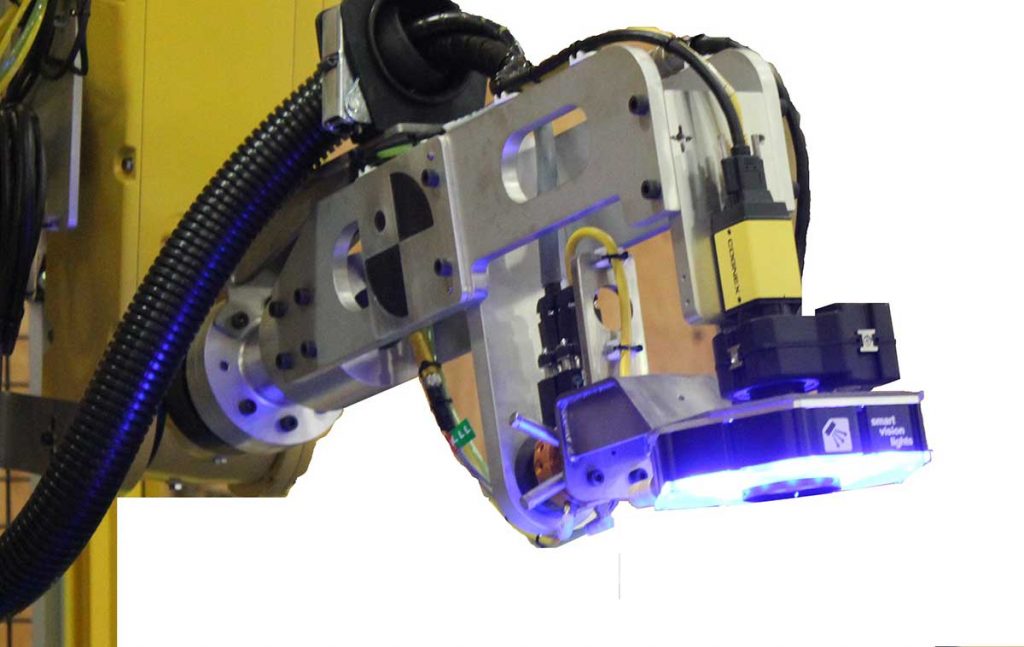

The system shown in the video below was custom designed by REMTEC to load dental burs onto multiple part model fixtures. The Remtec system operates using a FANUC SCARA SR-3iA Robot and iRVision, and includes nested drawers that hold multiple part fixtures, saves time by eliminating the need to presort parts.

A flexible part feeding system moves randomly positioned dental burs of varying shapes and sizes below a FANUC iRVision 2D guidance system vision sensor (camera). The FANUC SR-3iA SCARA Robot relies on iRVision and uses a one-axis gripper to accurately pick and orient the burs for placement into a specific fixture at high speeds. Once the dental burs have been loaded into the fixture, the SR-3iA robot transfers it onto an outgoing conveyor. The system then picks a new fixture model from a nested drawer and places it onto the worktable. At this point, the system begins loading burs that fit that fixture. The intelligent vision system and nested fixture drawers allow for on the fly loading of mixed parts to various fixture models.

A wide range of parts can be fed into the system, and only the correct parts are loaded as determined by the fixture model and user selected production schedule. This system is highly effective for a fast and simple part setup.

Remtec is your source for FANUC robots and experienced robotic integration. Contact us to discuss your needs.