Robots Offer Full Menu of Benefits in Food Industry

As rising prices continue to hit the food industry, manufacturers are discovering the benefits of robotic automation in decreasingcosts and improving bottom line. The high level of control and refinement intoday’s robotic technology makes it extremely conducive to a broad range of food industry applications.

Reduced Labor Costs | Increased Output | Safety

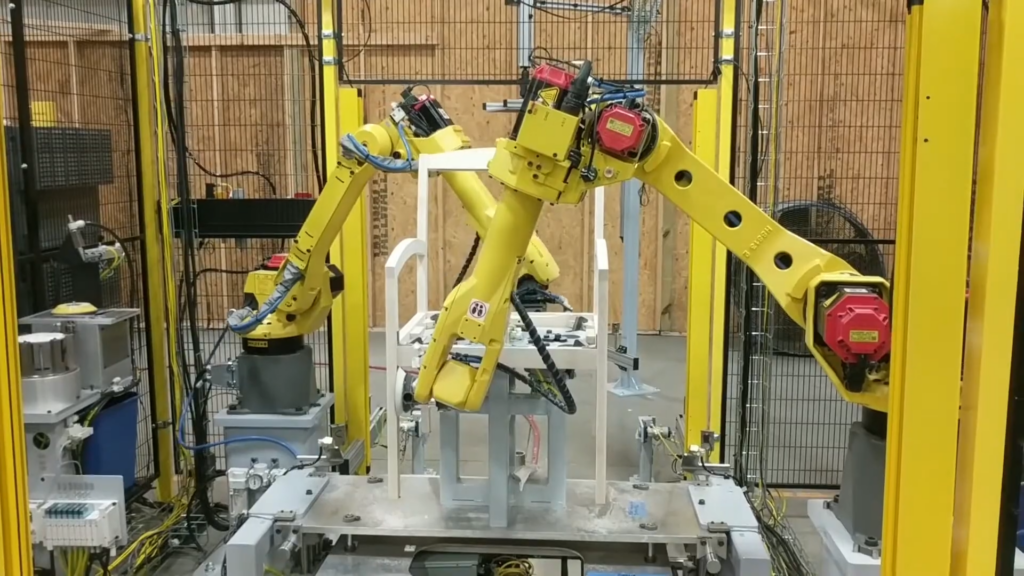

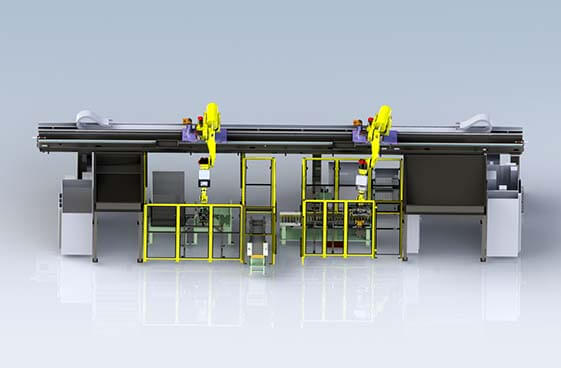

Robots used in food line applications increase productivity and volume for food manufacturers. The nature of food line operations includes highly repetitive motions performed at high speeds, which contribute to workplace injuries. Due to the risk factors, it is often difficult to find and retain labor for food line operations. Robots are highly effective and efficient in reducing labor costs, increasing output, and contributing to a safer environment.

Highly Adaptable: Some food industry products present a unique concern in the automation of operations due to inconsistencies in size and weight. Robotic technology is highly adaptable and able to compensate for issues with product variations.

Extreme Temperatures: Food industry applications often include environmental challenges, such as in the automation of frozen food operations. Robots are able to operate efficiently in extreme temperatures with certain adaptations.

Health & Cleanliness: Another advantage robotics offers in food industry applications is in meeting health and cleanliness standards. Robots can be sanitized and do not require the complications necessary to assure acceptable cleanliness standards with human labor.

Interested in learning more about how robotic automation could benefit your bottom line? Contact Remtec to request a quote, or call us to discuss your project.