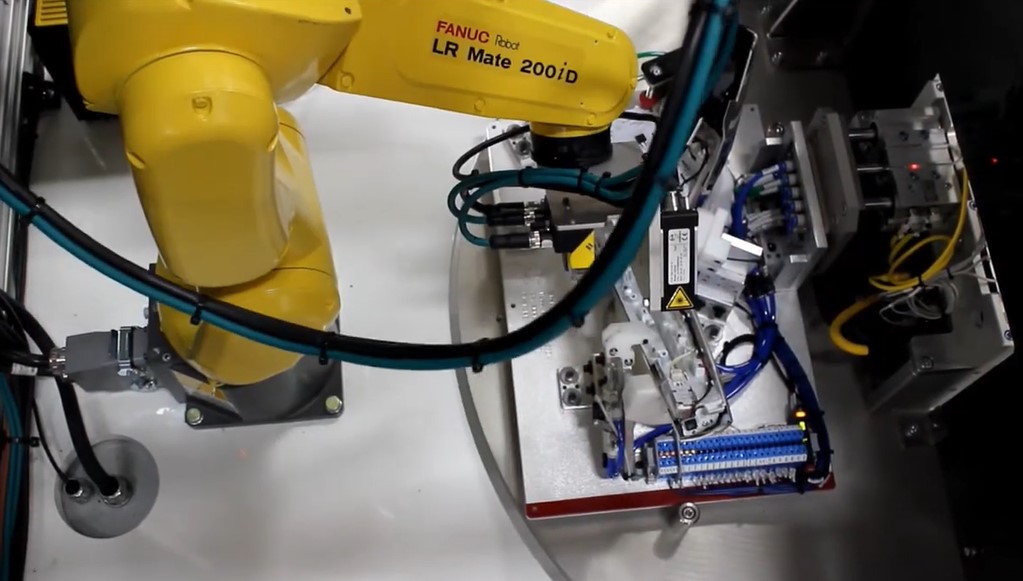

New Video Highlights Robotic Sanding System

Wood Furniture Sanding System Developed by Remtec

FANUC recently released a new video highlighting an automated robotic sanding system for wood chairs, which was developed by Remtec Automation. This automated system utilizes two FANUC M-10iA/10M robots equipped with FANUC FS-15iA Force Sensors to effectively and efficiently sand wooden chairs of varying profiles and styles.

The speed and consistency of robotic sanding has increased throughput with an average cycle time of three minutes per chair. This system also delivers enhanced safety by removing an operator from a dusty and dirty environment.

FANUC’s force sensing technology adapts application force, paths, and positions to accommodate variances in wood conditions and position by continually monitoring the amount of force applied during sanding

A variety of chair product lines with unique characteristics and details can be identified and processed on the line using RFID-based part identification. The adaptability of this system allows for the flexible processing of multiple chair types, while also improving consistency and quality.

To further enhance efficiency, the robotic sanding system incorporates an automated paper changer that loads fresh sanding sheets as needed, while the parts are changed.

Automated robotic system advantages:

- Speed and consistency increased – average cycle time of 3 minutes per chair

- Enhanced safety by removing an operator from dusty and dirty environment

The automated robotic sanding system was set to be released in conjunction with the now cancelled 2020 International Woodworking Fair, which would have taken place in Atlanta. If you had planned to attend the show, or are just interested in learning more about automated robotic sanding applications, contact us to discuss your project!